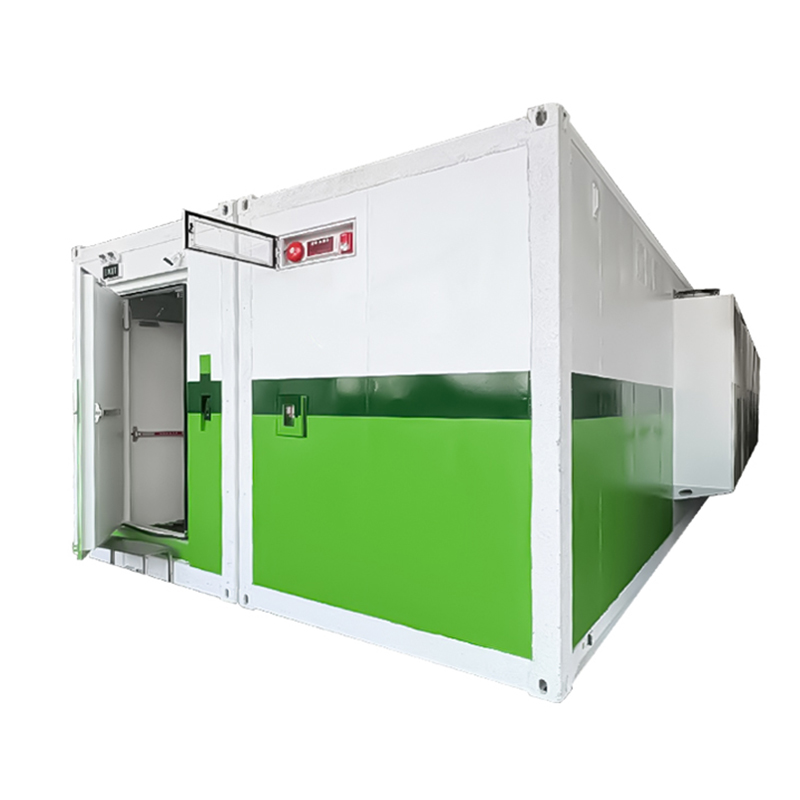

- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

About Us

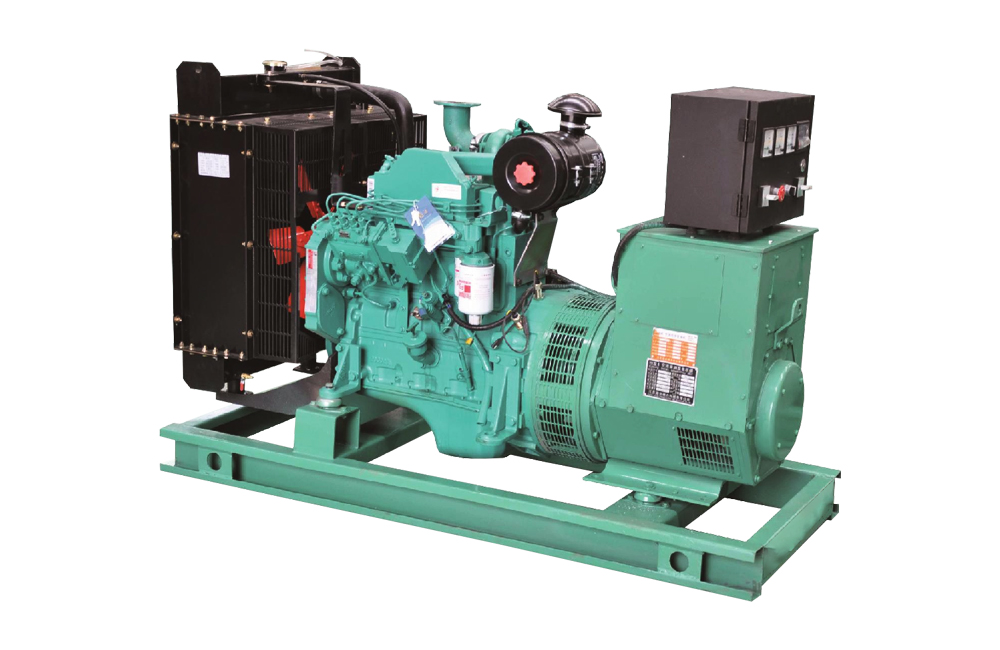

VENTTECH is a professional cooling equipment manufacturer and solution provider in the cooling industry, with the core direction of industrial cooling and immersion cooling.

Ranking customers' needs first, VENTTECH is committed to producing good products with more reasonable price, lower running loss and higher quality. We also have a strong R&D team and a sound quality management system, supporting our independent R&D capabilities.

Above all else, manufacturing is of primary importance. Venttech has specialized factories in China to support the sales department in Shanghai.

Over the past 17 years, VENTTECH heat exchangers perform well in air conditioners, heat pumps, fan coil units, air handling units, electric welding machines and so on. VENTTECH keeps serving customers from the fields such as air conditioning, electronics, and industrial sectors, focusing on creating commercially viable solutions and cooling products for high-density applications.

For Microchannel and Tube Fin Heat Exchangers, VENTTECH is skilled at designing and producing customly. The available materials include copper, aluminum, titanium, stainless steel and alloys. All kinds of Heat exchange tubes, fins, structural parts, and pipes can be selected to meet different environments or requirements, such as seawater corrosion.

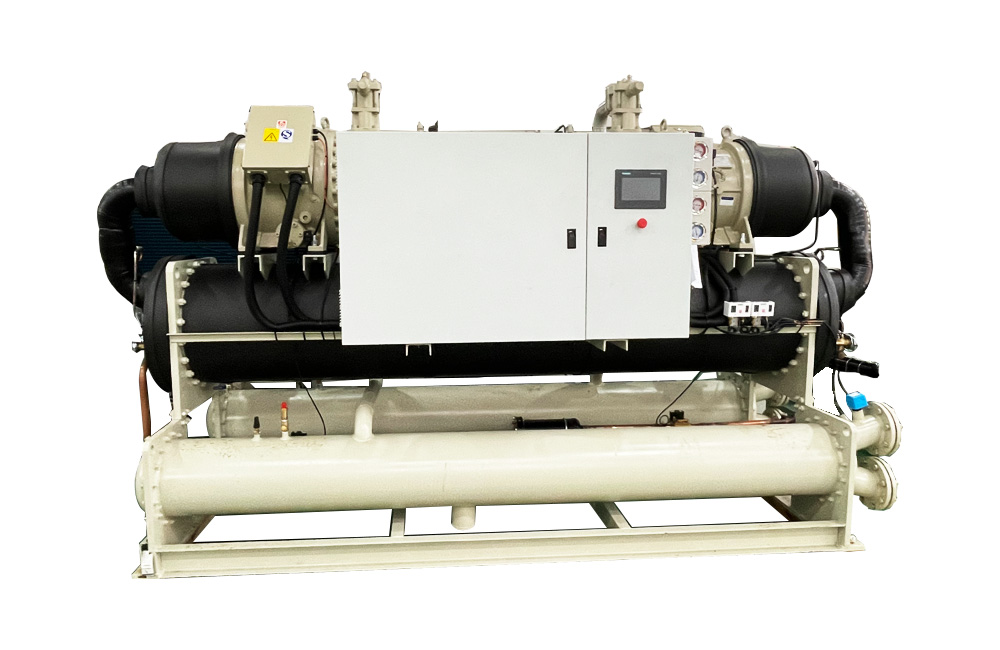

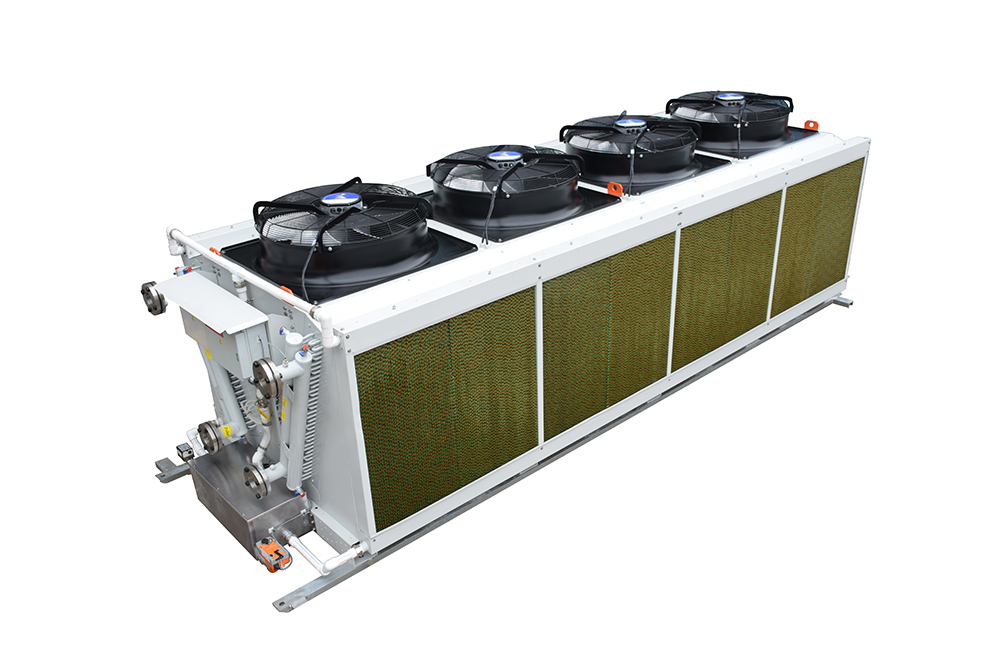

Furthermore, VENTTECH is constantly updating the immersion cooling technology with dry coolers as the core. This technology is widely used in the cooling of high-density computing equipment such as supercomputing centers, data centers, and IDC computer rooms, and telecom computer rooms. Immersion liquid cooling can significantly reduce the energy consumption of related industries, improve efficiency, and make great achievements in the three major fields of new energy, information, and the Internet.

Believe in VENTTECH, and we will do our best to satisfied your needs.

Venttech Dry Cooler Introduction

VENTTECH REFRIGERATION

Dry Cooler References

Venttech Fin Tube Heat Exchanger Introduction

WHY VENTTK

VENTTK is a leading design and manufacturing company specializing in Fin Heat Exchangers.

Our experienced engineers use Italy's cutting-edge Mcoil thermal calculation software to design top-notch heat exchangers. With their expertise, we are able to produce precise drawings and performance calculation books.

Regarding production, we have state-of-the-art facilities that house multiple production lines dedicated to finned tube heat exchangers.

Our sheet metal production lines are equipped with advanced laser cutting machines, CNC punch presses, CNC bending machines, and stretching hydraulic devices for guide rings.

Additionally, our tube-expanding equipment includes both mechanical and hydraulic tube expanders.

VENTTK employs gas welding and argon arc welding techniques, and we also offer spray coating and electrophoretic processes to meet our customers' unique requirements.

At VENTTK, quality is our priority. Our Tube Fin Heat Exchangers are of the highest standard and hold international certifications such as Rohs, CE, and UL, which are widely recognized across the globe.

Factory Tour

Production Equipments

Helium Test Equipment

Laser Welding Equipment

Laser Cut Equipment

Fully Automatic Baffle Mounting Equipment

Automatic Coating Equipment System

Automatic Assembly Machine

Ventttech has many years of export experience.

We have established a good cooperative relationship with our customers, so that our products have gone out of China and exported to more than 60 countries and regions such as the United States, Russia, Canada, Europe, the United Arab Emirates, Singapore, Brazil, etc.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)