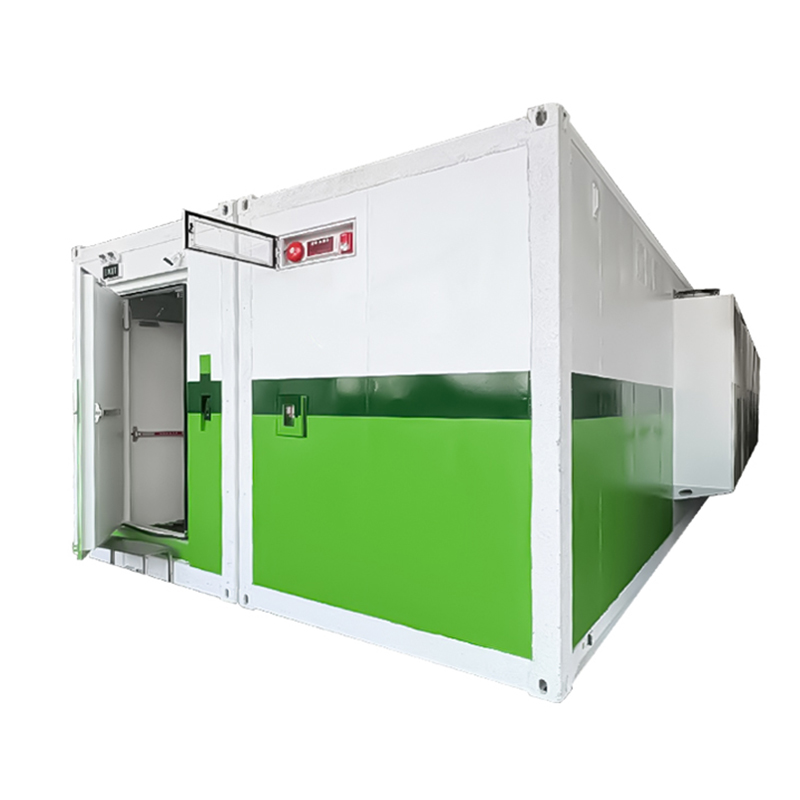

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

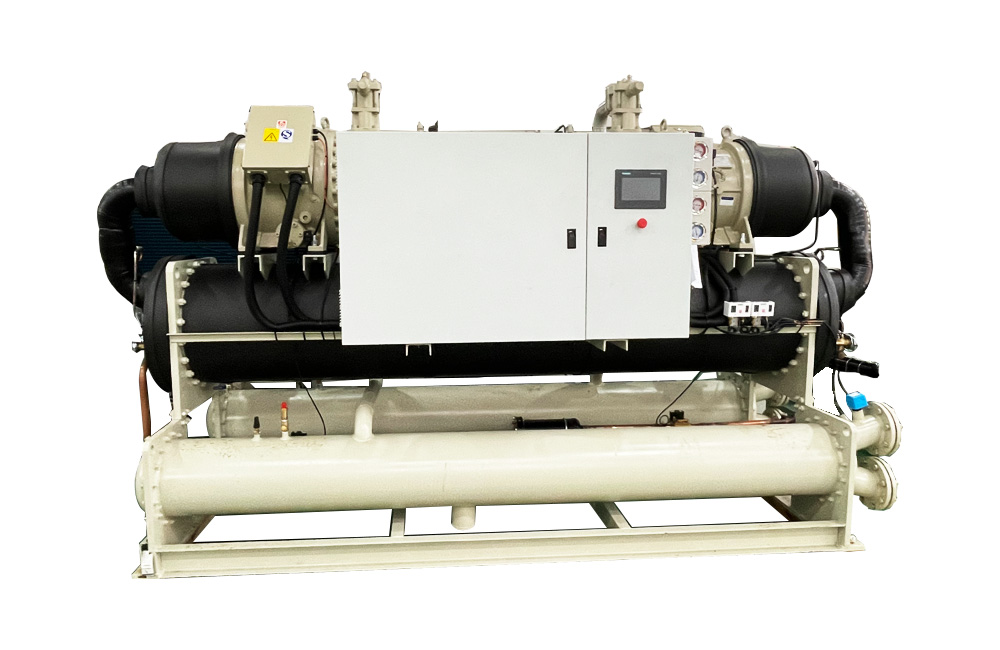

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

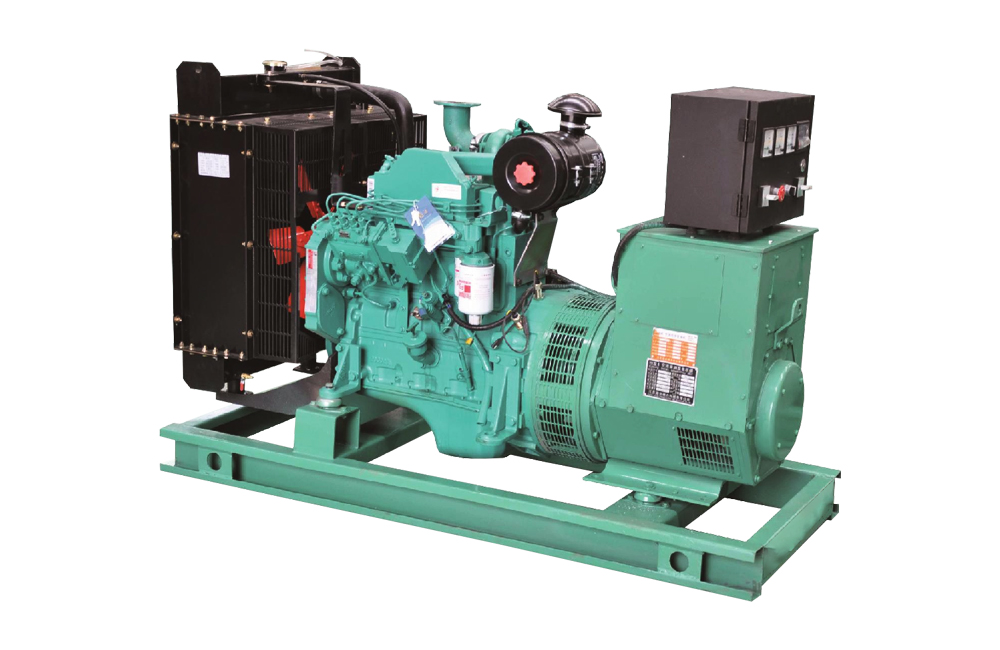

- Cabinet Cooling System

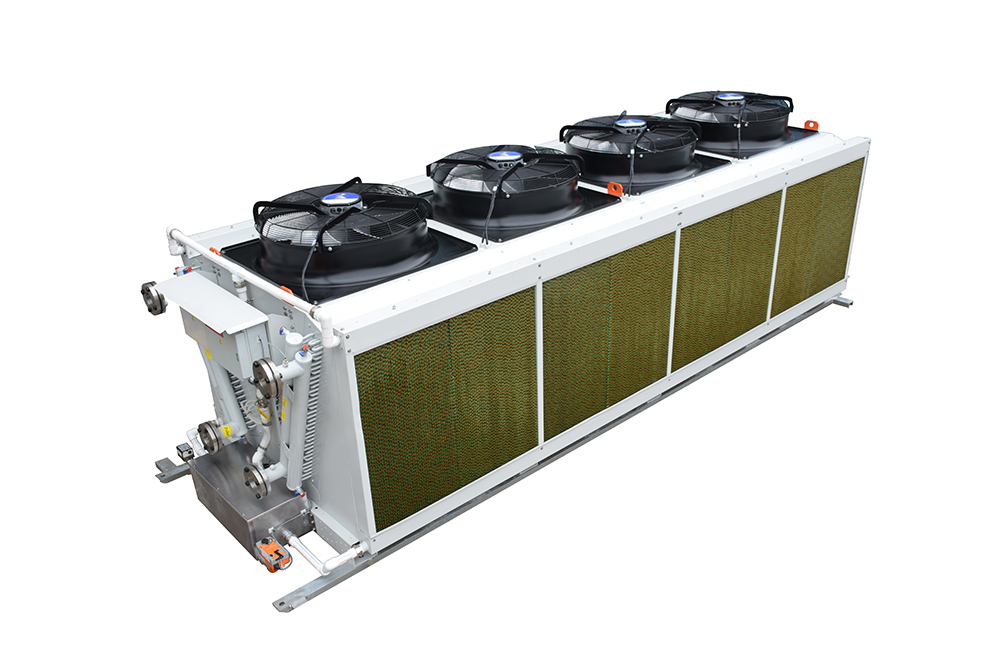

Adiabatic dry cooler are air-cooled coolers with adiabatic pre-coolers. Before the fan draws the ambient air through the coil, the air is pre-cooled adiabatically when traversing an humidification pad. This evaporates the water in the air, thus boosting the cooling capacity.

Key benefits

● Low process temperatures

● Saves more than 80% on annual water compared to cooling towers

● Up to 40% increased capacity compared to dry cooling (air temperatures approaching wet bulb temperature)

● Reduced energy consumption

● Operational safety: no water recirculation, no stagnant water, no aerosol generation, no water carry-over.

Performance range:

● Capacity from 69to 3212kW

(water, Tw1=40°C, Tw2=35°C, T1=25°C)

Fans:

● Diameter Ø630, 800, 910, 1250, 1800mm, AC or EC motor.

Benefits:

● Maximum performance, minimum footprint.

● High efficiency geometry.

● Modular design, 1~28fans.

● Piping in copper or stainless steel AISI 304 or AISI 316L.

● Finned pack available in a wide range of materials.

Options:

● Coil design refrigerant: water, oil, glycol, BC888, Shell S3X and S5X.

● Multiple circuits.

● Sub-cooling circuits.

● Stainless steel or aluminum casing.

● Epoxy resin aluminum or copper fins.

● Explosion proof motor.

● Customized fin spacing.

● Spray system

What is adiabatic cooling?

Adiabatic cooling systems function similarly to dry cooling systems, but with the incorporation of pre-cooling pads; running water over pre-cooling pads and drawing air through the pads depresses the ambient dry bulb of the incoming air. The depressed dry bulb allows for greater system heat rejection.

Venttech, a leading designer and manufacturer of adiabatic coolers and can help you find the right solution for your operation.

Adiabatic coolers work in much the same way as a dry cooler for most of the year, but they also come fitted with an adiabatic spray system that is the final stage of cooling that is only employed during the hottest times of the year.

This final stage of cooling works by water being sprayed into the air stream, as the air is drawn across the coil by the fans. The sprayed water evaporates into the air stream and thus cools the air before it passes over the coil and so enables a greater cooling effect on the coil. This enables the cooler to cool the media (generally a water/glycol solution) to within 5°C of the wet bulb ambient temperature. The water that is used for this is direct from the mains supply and is not recirculated like in a cooling tower.

Another benefit of using an adiabatic cooler over a dry air cooler is that due to the efficiencies of the adiabatic system, the unit is typically of a smaller footprint which can assist when space is at a premium. We can also provide the same cooler orientations and options as our dry air cooler range.

Where are adiabatic cooling systems a good fit?

Adiabatic cooling systems can be a good technical and economic fit in hot, dry climates, especially where water supplies are scarce and costs are high. They can also be a good match where outside air temperatures are cool enough for most of the year for air-cooled fluid coolers or refrigerant condensers to operate efficiently.

The data center industry has employed adiabatic cooling technology on the air side for air handlers for years. With the development of new adiabatic designs applied to fluid coolers and refrigerant condensers and the increasing scarcity of water, adiabatic cooling systems are seeing wider use across a range of industries and applications.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)