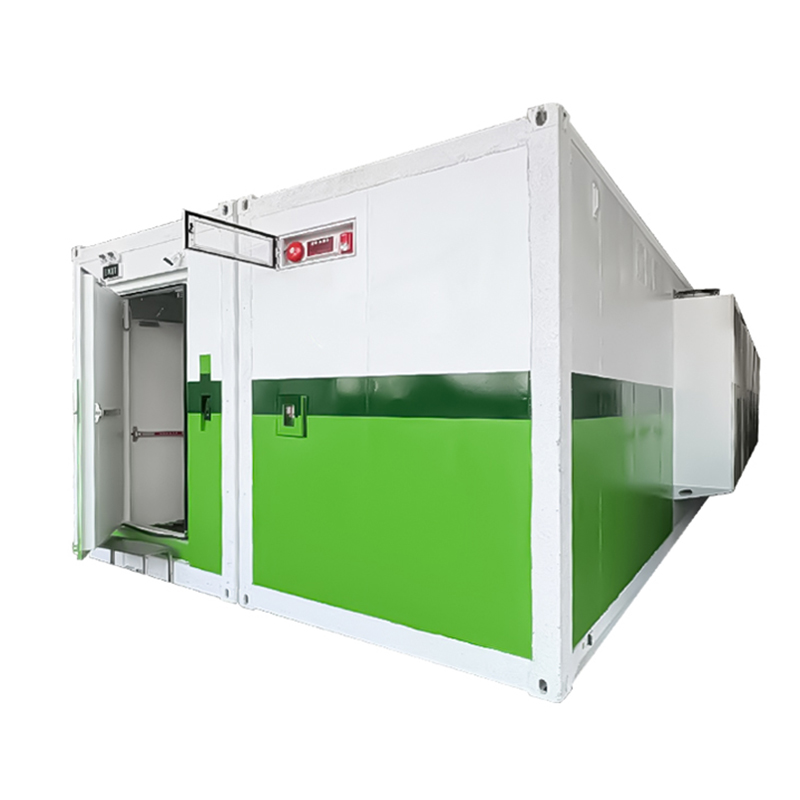

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

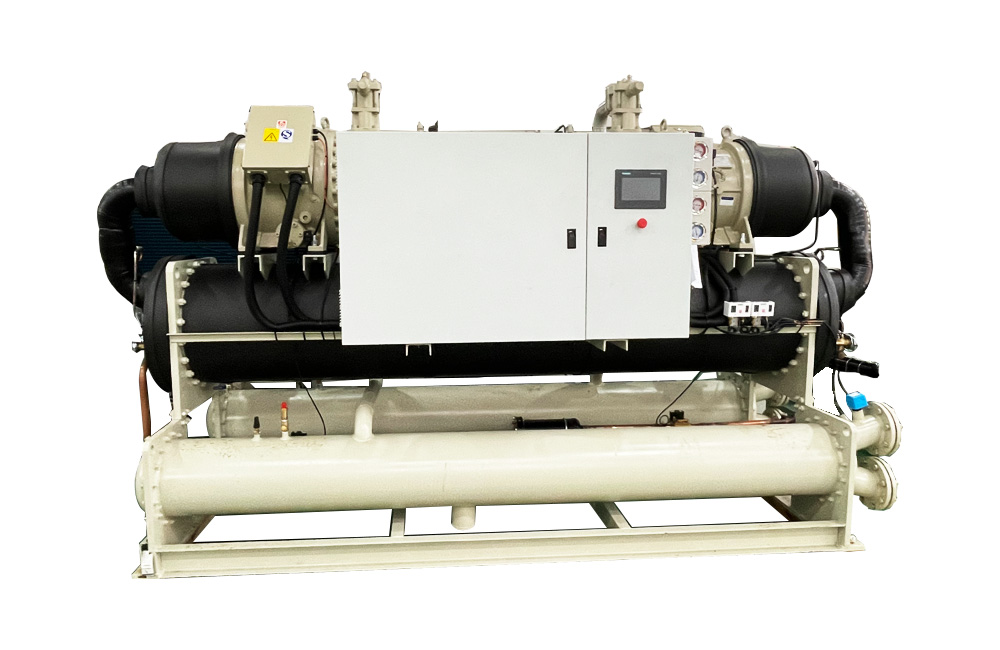

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

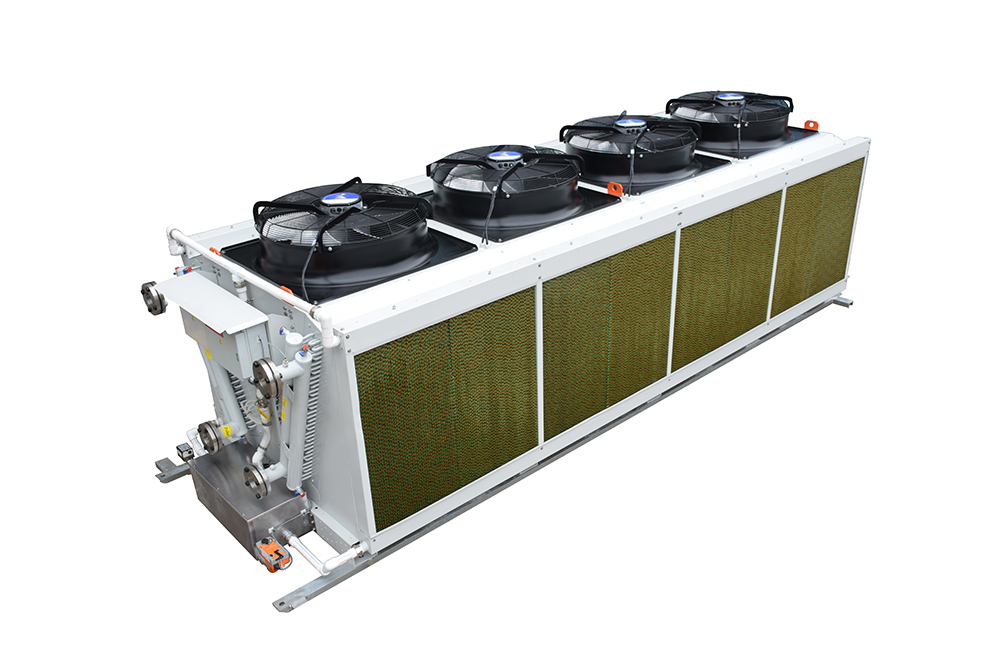

Dry cooler Auxiliary System:

1. The spray system:

The spray system uses intermittent atomized water to spray on the intake flow to provide an adiabatic cooling effect, reducing the air temperature to near the wet bulb temperature, thereby helping to save a lot of energy and increase work. Improving heat exchange efficiency can increase heat dissipation under the same heat exchange area.

Adding a spray system to the induction cooling system can take away the heat of the circulating water in the data center for most of the year. The spray system increases the heat transfer capacity of the dry cooler, further reducing the operation of mechanical refrigeration.

2. Wet curtain(cooling pad) system:

This type of adiabatic pre-cooling allows return and condensation temperatures below the ambient temperature or a considerably higher unit performance with the same space requirements and improved system efficiency.

Performance range:

● Capacity from 5 to 1920kW

(water, Tw1=40°C, Tw2=35°C, T1=25°C)

Fans:

● Diameter Ø350, 450, 500, 630, 800, 910, 1250, 1800mm

● AC or EC motor

Benefits:

● Maximum performance, minimum footprint

● High efficiency geometry

● Modular design, 1~8 fans

● Piping in copper or stainless steel AISI 304 or AISI 316L

● Wide range of fin materials available

Options:

● Coil design refrigerant: water, oil, glycol, BC888, Shell S3X and S5X

● Multiple circuits

● Sub-cooling circuits

● Stainless steel or aluminum casing

● Epoxy resin aluminum or copper fins

● Explosion proof motor

● Customized fin spacing

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)