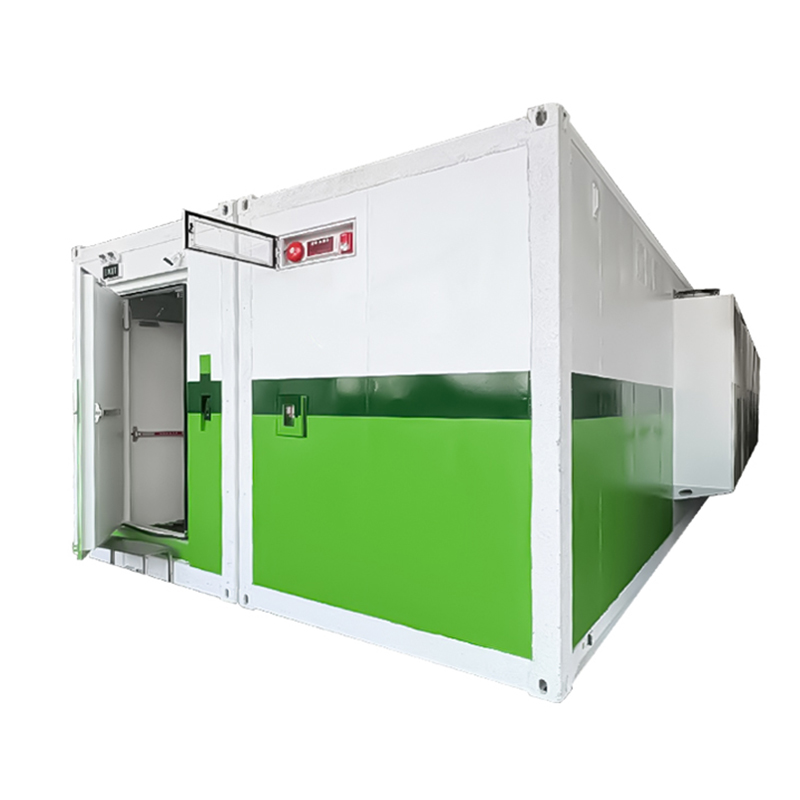

- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

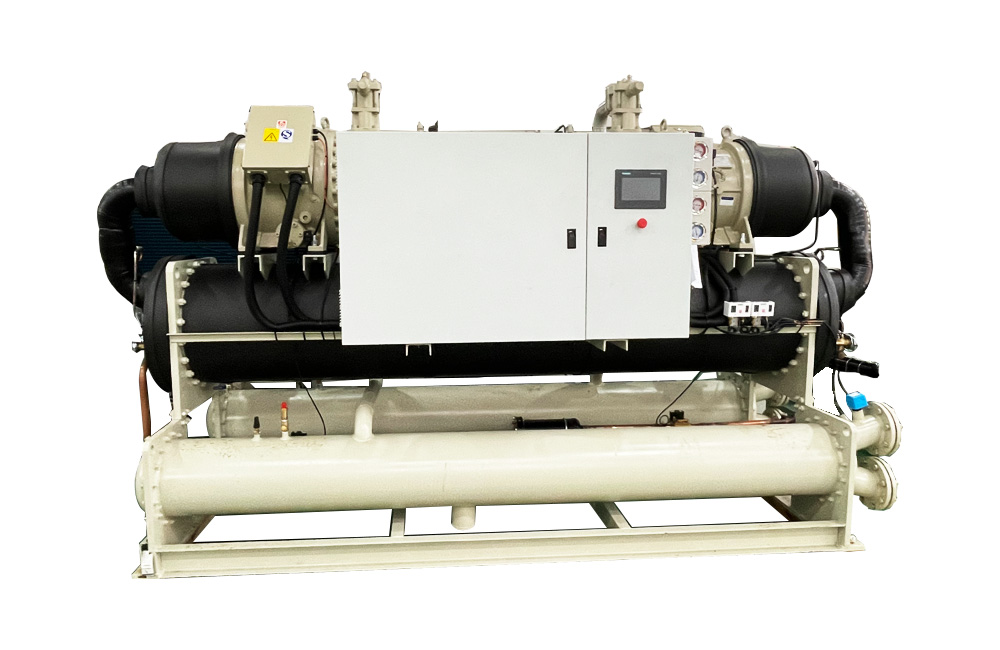

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Design and Structure Features:

1. Use of Cross-Flow Cooling Method: Achieving a low water rate.

2. Large Interior Space: Convenient maintenance.

3. Fully Enclosed Circulation: Preventing clogging caused by debris.

4. Modular Heat Exchange: Easily install and remove layers.

5. Compact Design: No need for a sink, small footprint, and easy access.

6. Automatic Temperature Control: Energy-saving and environmentally friendly.

7. Simple Operation: Low maintenance cost.

Product Performance:

The Closed-Type Cooling Tower utilizes a combination of water and air, along with a mixed flow and two-stage heat exchange coil and PVC packing technology, to achieve highly efficient heat exchange. The coil's surface is fully moistened as the air and spray water flow through it, minimizing the formation of dry points and scale on the coil wall.

Structural Characteristics:

1. High-Efficiency Spray Water Circulation System

Venttk Cooling Tower utilizes the latest ABS special spray nozzles, providing a large amount of uniform water distribution without clogging. The water film formed on the outer wall of the coil enhances heat exchange and reduces corrosion. An outdoor circulating water pump further reduces energy consumption and maintenance requirements.

2. High Efficiency and Low Noise Fan

Venttk Cooling tower employs a high-efficiency and low-noise fan that features broad-leaved, large chord length, space-twisted aluminum alloy blades. This fan ensures high efficiency, low vibration, low noise, and energy savings. The direct-linking design eliminates the need for deceleration and facilitates maintenance. The motor used is an outdoor type, high-temperature resistant sealed motor.

3. Solid Corrosion-Resistant Tower Body

To ensure normal operation in harsh environments, Venttk Cooling tower body and water-collecting chassis are constructed with stainless steel folding plates. The tower plate and fan cylinder are made with corrosion-resistant FRP components, and all connectors are stainless steel.

4. Efficient Water-Collecting Device

Venttk Cooling tower incorporates a three-dimensional water collector made of FRP material, which offers minimal air resistance and high water efficiency (>999% in the cycle). The detachable design facilitates internal maintenance.

Applications:

1. Cooling for Medium Frequency and High-Frequency Power Supplies

2. Cooling for Medium-Frequency Quenching of Workpieces

3. Cooling for Vacuum Heating, Sintering, Welding, and Melting Furnaces

4. Cooling for Air Compressors

5. Cooling for Central Air Conditioning Systems

6. Cooling for Water-Cooled Screw Machines and Plate Exchangers

7. Cooling for Screw Machines and Other Equipment

Features of Closed Cooling Tower Components

1. Fan

The ventilation system utilizes specialized aluminum alloy axial flow fans for cooling towers. With a forward-leaning blade structure and streamlined inlet duct, it offers low wind resistance, high air volume, low noise, excellent performance, and high efficiency. The structure eliminates belt transmission, reducing the number of moving parts. It also features a fully enclosed self-cooling low-noise motor specifically designed for cooling towers, which is compact, lightweight, has excellent startup performance, reliable operation, and durability.

2. Spray System

The cooling tower adopts a sealed water pump specifically designed for cooling towers. It provides a large flow rate, low lift, high efficiency, low noise, and low power consumption. The evaporative condenser has a dedicated water pump that meets JIS-C4210 standards. The pump motor operates at a voltage of 380V and has an IP55 protection rating and F-class insulation rating.

3. Fill

Venttk Cooling tower utilizes specially designed PVC honeycomb cross-flow fill with a shortcut crosswind structure. This design allows air to carry away heat from the water quickly. The unique fill flow path enables the formation of a large area of flowing water film on the fill surface, extending the cooling time of the water in the fill and enhancing the cooling effect. It has the advantages of low wind resistance, resistance to aging, and deformation resistance.

4. Water Distribution System

The circulating water pump adopts a closed cooling tower specialized pipeline pump, providing stable performance and low noise. The pump motor has an IP55 protection rating and F-class insulation rating. The circulating water tank is made of SUS304 stainless steel plate, formed by stamping, and has an aesthetically pleasing appearance and strong pressure resistance to the circulation system.

|

Model |

Cooling Capacity |

Cooling Flow |

Working Pressure |

Spray Pump |

Fan |

Inlet outlet Pipe |

Overall Dimension |

Weight |

|||||

|

LBN- |

5℃28WB |

|

Input power |

Flow |

Input power |

Flow |

DN |

L |

W |

H |

Net |

Running |

|

|

6T |

30000 |

6 |

0.1 |

0.55 |

20 |

0.55 |

8300 |

65 |

2200 |

1000 |

1980 |

350 |

500 |

|

10T |

50000 |

10 |

0.1 |

0.55 |

20 |

0.75 |

12500 |

65 |

2300 |

1000 |

2000 |

450 |

720 |

|

15T |

75000 |

15 |

0.15 |

0.55 |

20 |

0.55x2 |

16600 |

65 |

2300 |

1000 |

1980 |

530 |

850 |

|

20T |

100000 |

20 |

0.15 |

0.55 |

20 |

0.75x2 |

25000 |

65 |

2300 |

1000 |

2000 |

580 |

890 |

|

25T |

125000 |

25 |

0.2 |

0.75 |

34 |

0.75x2 |

25000 |

80 |

2800 |

1250 |

2200 |

750 |

1520 |

|

30T |

150000 |

30 |

0.2 |

0.75 |

34 |

1.1x2 |

31000 |

80 |

2800 |

1250 |

2200 |

830 |

1650 |

|

40T |

200000 |

40 |

0.2 |

0.75 |

34 |

1.1x2 |

31000 |

100 |

2900 |

1250 |

2760 |

960 |

1650 |

|

50T |

250000 |

50 |

0.25 |

1.1 |

60 |

1.5x2 |

36000 |

100 |

2900 |

1500 |

2760 |

1050 |

2080 |

|

60T |

300000 |

60 |

0.25 |

1.1 |

60 |

1.5x2 |

36000 |

100 |

3000 |

1750 |

3000 |

1220 |

2260 |

|

70T |

350000 |

70 |

0.3 |

1.5 |

87 |

1.1x4 |

50000 |

125 |

3200 |

2000 |

3000 |

1350 |

2720 |

|

80T |

400000 |

80 |

0.3 |

1.5 |

87 |

1.1x4 |

50000 |

125 |

3200 |

2200 |

3000 |

1550 |

2980 |

|

100T |

500000 |

100 |

0.3 |

2.2 |

100 |

1.5x4 |

72000 |

150 |

3600 |

2200 |

3000 |

1780 |

3080 |

|

125T |

625000 |

125 |

0.3 |

2.2 |

100 |

1.5x4 |

72000 |

150 |

3600 |

2200 |

3220 |

1980 |

3280 |

|

150T |

750000 |

150 |

0.3 |

2.2 |

100 |

2.2x4 |

100000 |

150 |

3660 |

2200 |

3380 |

2350 |

3980 |

|

180T |

900000 |

180 |

0.3 |

4 |

100 |

5.5x4 |

146000 |

150 |

3900 |

2300 |

3420 |

2680 |

4650 |

|

200T |

1000000 |

200 |

0.4 |

4 |

100 |

5.5x4 |

146000 |

150 |

4800 |

2300 |

3480 |

3180 |

4780 |

|

250T |

1250000 |

250 |

0.4 |

2.2x2 |

200 |

7.5x2 |

162000 |

200 |

5200 |

2300 |

3680 |

4180 |

5570 |

|

300T |

1500000 |

300 |

0.5 |

2.2x2 |

200 |

7.5x2 |

162000 |

200 |

5500 |

2300 |

4210 |

4850 |

5980 |

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)