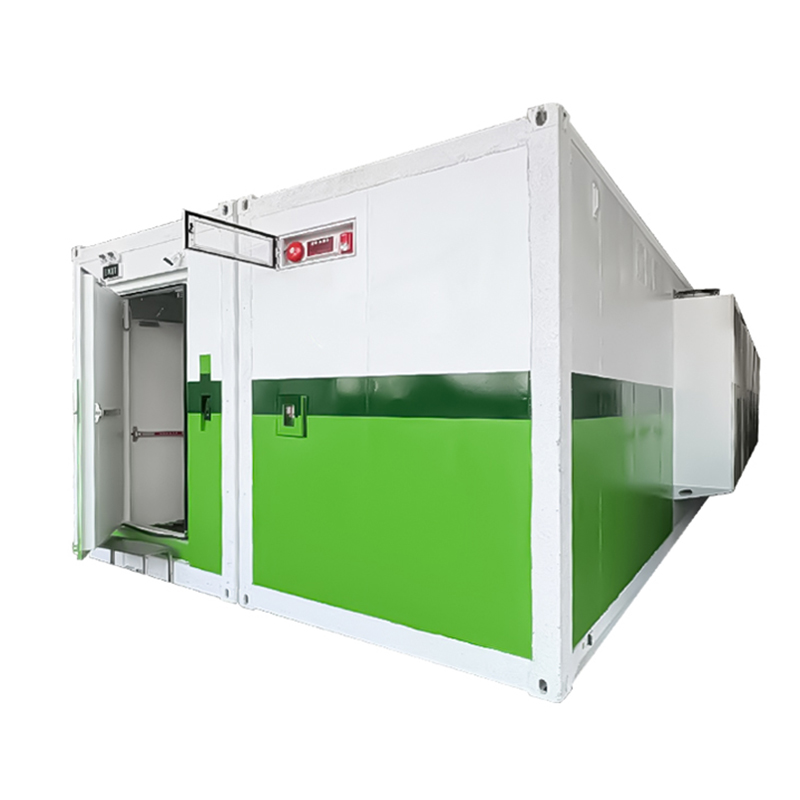

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

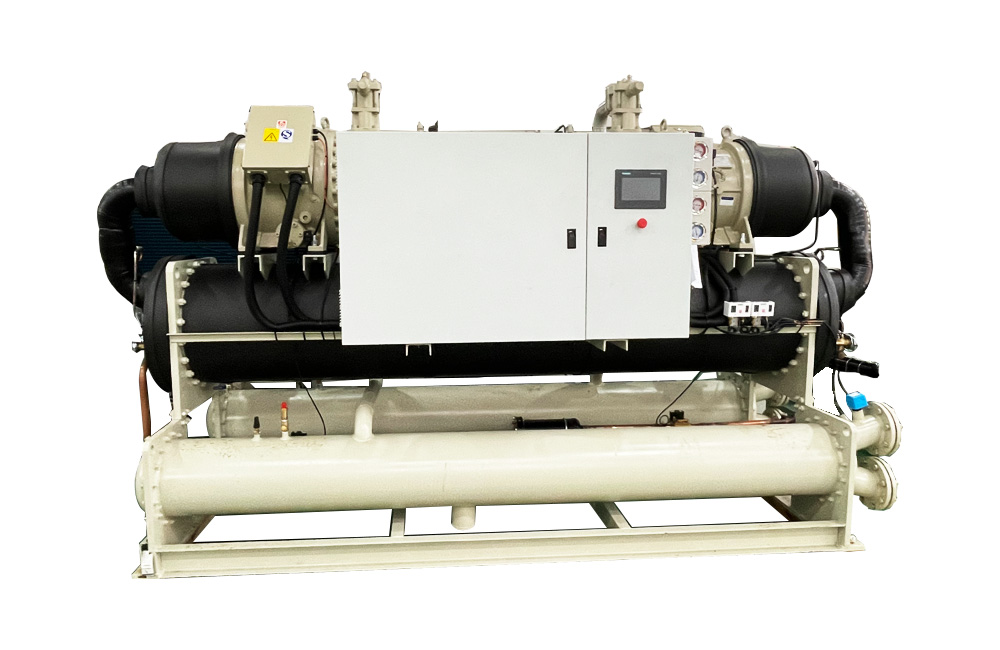

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

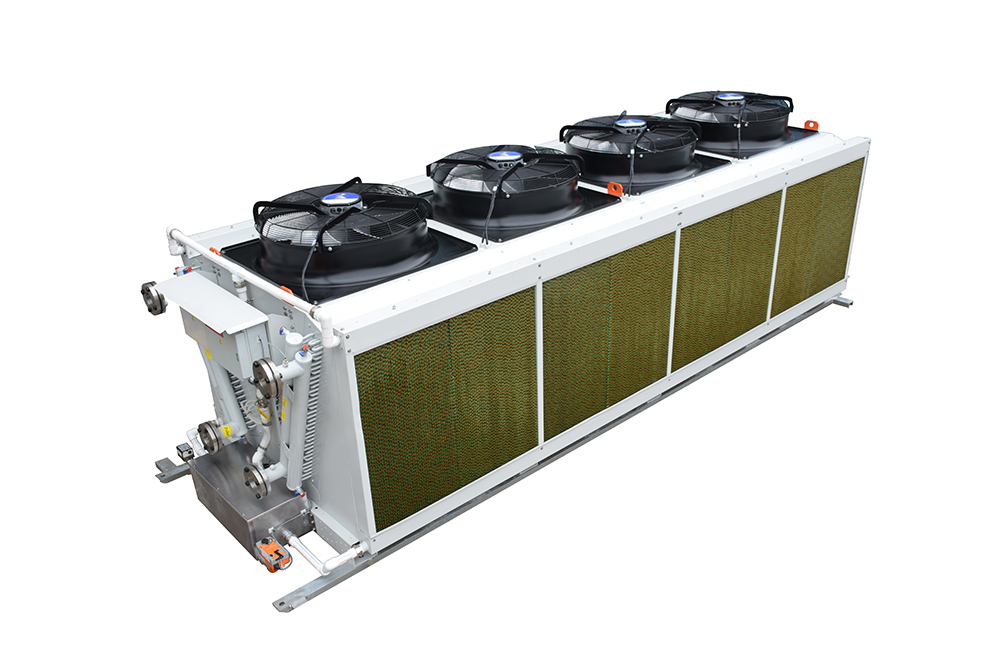

Open-Type Crossflow Cooling Tower is a type of cooling device where air flows horizontally through the fill material as water moves vertically, distinguishing it from Closed-Type towers where air and water flow in the same direction, and Counterflow towers where air flows vertically against the downward flow of water. Its key feature is efficient heat dissipation through crossflow design.

The filler adopts point wave plates with coated dots on both sides, which are bonded together as a whole through the installation head to improve rigidity. The convex points on both sides can also avoid direct dripping. This tower has the characteristics of durability, low noise, environmental protection, and minimal maintenance

Applications

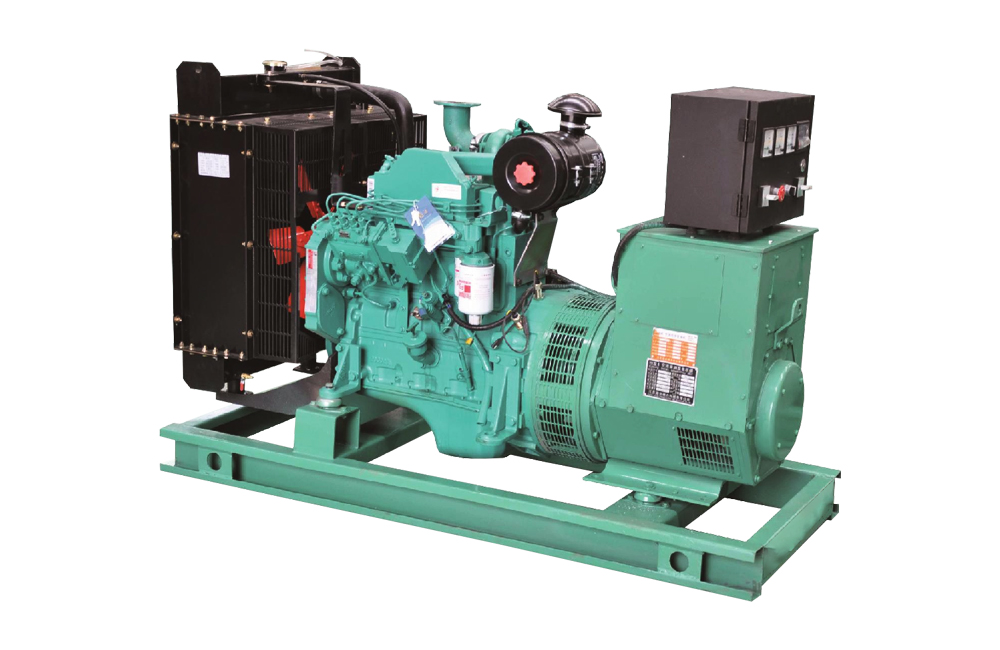

Cooling for medium and high frequency power supplies.

Cooling for medium-frequency quenching workpieces and quenching liquids.

Ideal for vacuum heating, sintering, welding, and melting furnaces.

Reliable cooling solution for air compressors.

Essential for central air conditioning systems.

Efficient cooling for water-cooled screw machines and plate exchangers.

Versatile cooling solution for screw machines and other equipment.

Component Introduction

|

MODEL |

OVERALL DIMENSION |

FLOW RATE (m3/h) |

FAN (mm) |

MOTOR (hp) |

WEIGHT (kg) |

NOISE(dB) |

|||||

|

L |

W |

H |

H1 |

H2 |

NET |

RUNNING |

|||||

|

LYR-100L/S |

1790 |

3300 |

3700 |

2300 |

700 |

100 |

1470 |

2 |

995 |

1610 |

58.5 |

|

LYR-125L/S |

2360 |

3600 |

3700 |

2300 |

700 |

125 |

1800 |

5 |

1100 |

2620 |

59.5 |

|

LYR-150L/S |

2650 |

3900 |

3700 |

2300 |

700 |

150 |

2100 |

5 |

1230 |

2830 |

60.5 |

|

LYR-175L/S |

2650 |

3900 |

3700 |

2300 |

700 |

175 |

2100 |

7.5 |

1350 |

3150 |

60.5 |

|

LYR-200L/S |

3090 |

4300 |

3700 |

2300 |

700 |

200 |

2400 |

7.5 |

1490 |

3580 |

61.5 |

|

LYR-225L/S |

2900 |

4990 |

4080 |

2680 |

700 |

225 |

2400 |

7.5 |

1650 |

3470 |

61.5 |

|

LYR-250L/S |

3150 |

4990 |

4080 |

2680 |

700 |

250 |

2400 |

10 |

2320 |

4520 |

62.0 |

|

LYR-300L/S |

3500 |

5590 |

4080 |

2680 |

700 |

300 |

3000 |

15 |

2520 |

5580 |

62.5 |

|

LYR-350L/S |

3600 |

5590 |

4080 |

2680 |

700 |

350 |

3000 |

15 |

2790 |

5920 |

63.0 |

|

LYR-400L/S |

3840 |

5930 |

4230 |

2680 |

850 |

400 |

3330 |

15 |

3190 |

6630 |

63.5 |

|

LYR-450L/S |

4090 |

5930 |

4230 |

2680 |

850 |

450 |

3330 |

20 |

3600 |

7290 |

63.8 |

|

LYR-500L/S |

4350 |

6080 |

4850 |

3300 |

850 |

500 |

3330 |

20 |

4200 |

8150 |

64.2 |

|

LYR-600L/S |

4650 |

6400 |

4850 |

3300 |

850 |

600 |

3700 |

25 |

4620 |

8960 |

65.0 |

|

LYR-700L/S |

4950 |

6400 |

5450 |

3900 |

850 |

700 |

3700 |

30 |

5040 |

9610 |

66.5 |

|

LYR-800L/S |

5250 |

6900 |

5500 |

3900 |

900 |

800 |

4200 |

30 |

5620 |

10710 |

67.0 |

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)