- Immersion Cooling Container

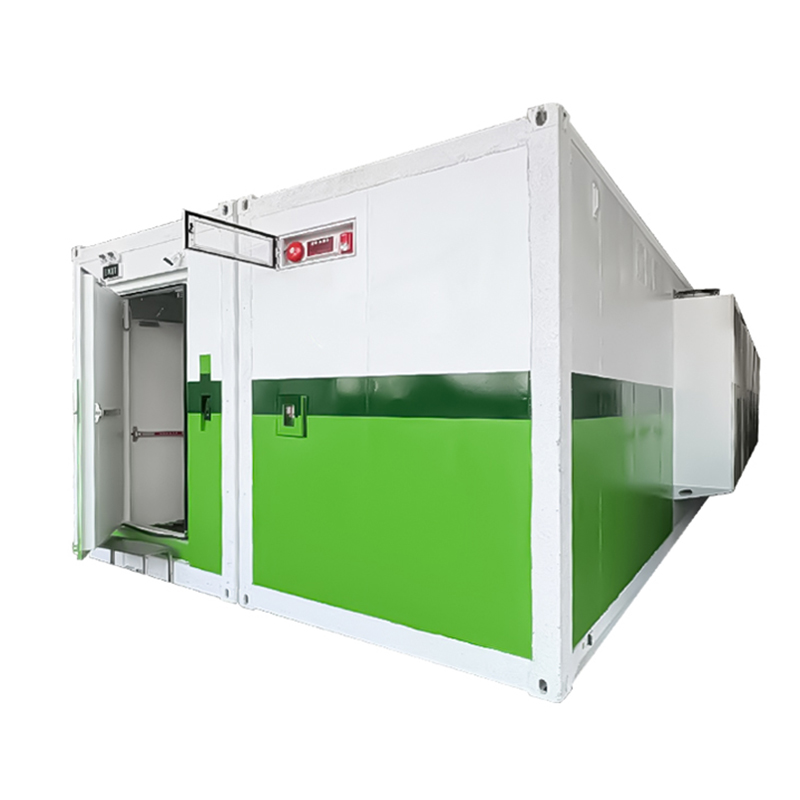

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

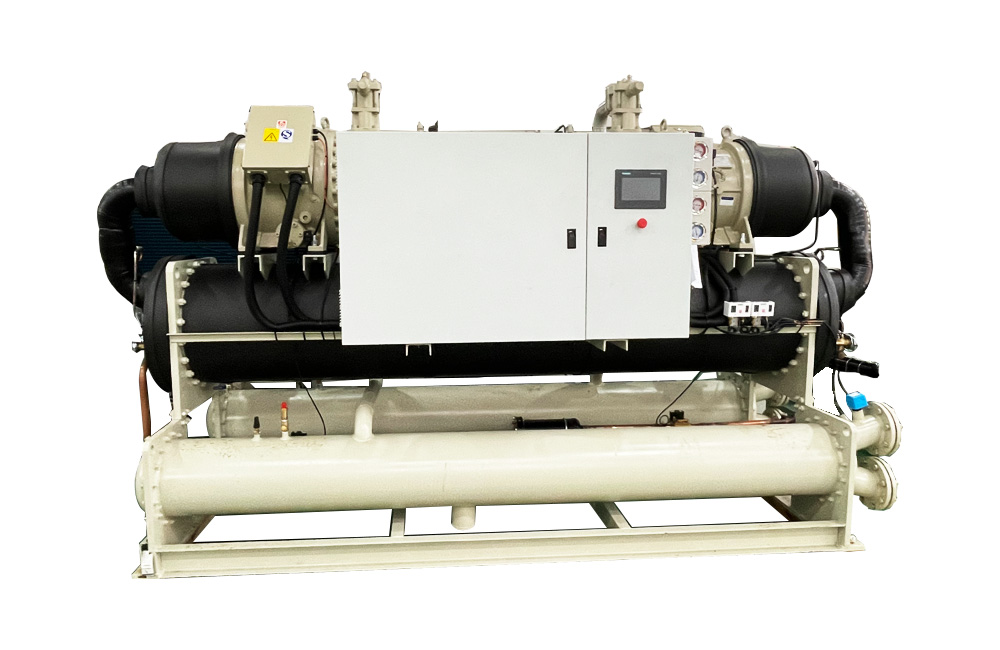

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Product Description

Data centre coolant DC3 series is made of propylene glycol, highly efficient corrosion inhibitor and high purity water. This product is pre-diluted cooling liquid, can be used directly.

|

PROJECT

|

DC3-10

|

TEST METHOD

|

||

|

Appearance

|

Clear and transparent liquid without

precipitation and suspension

|

Visual estimation

|

||

|

Color

|

Red

|

Visual estimation

|

||

|

Density(20.0℃)/(g/cm3)

|

1.029 |

SH/T 0068

|

||

|

Freezing point/℃

|

-11.4 |

SH/T 0090

|

||

|

Boiling point/℃

|

102.4 |

SH/T 0089

|

||

|

Ash content(Mass fraction)/%

|

0.35 |

SH/T 0067

|

||

|

pH value

|

8.3 |

SH/T 0069

|

||

|

Chlorine content/(mg/kg)

|

2 |

SH/T 0621

|

||

|

Reserve alkalinity/ml

|

2.3 |

SH/T 0091

|

||

|

Effect on organic coatings

|

No impact

|

SH/T 0084

|

||

|

Corrosion of

glassware

(88℃±2℃,

336h±2h)

|

Change

in mass

(mg/Test

piece)

|

Purple copper

|

1.1 |

SH/T 0085

|

|

Brass

|

0.7 | |||

|

Steel

|

0.9 | |||

|

Cast iron

|

1.4 | |||

|

Solder

|

1.5 | |||

|

Cast aluminium

|

1.2 | |||

|

Corrosion of

glassware

(88℃±2℃,

1064h±2h)

|

Change

in mass

(mg/Test

piece)

|

Purple copper

|

2.2 |

SH/T 0085

|

|

Brass

|

2.0 | |||

|

Steel

|

1.7 | |||

|

Cast iron

|

2.3 | |||

|

Solder

|

2.7 | |||

|

Cast aluminium

|

1.9 | |||

|

Bubble tendency

(88℃±1℃)

|

Foam volume/ml

|

30 |

SH/T 0066

|

|

|

Foam disappearance time/s

|

1.0 | |||

|

Heat transfer corrosion of aluminium alloy

(135℃±1℃, 168h±2h)Mass change rate/(mg/cm2)

|

0.2 |

SH/T 0620

|

||

Note: Customized products for other working conditions are available.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)