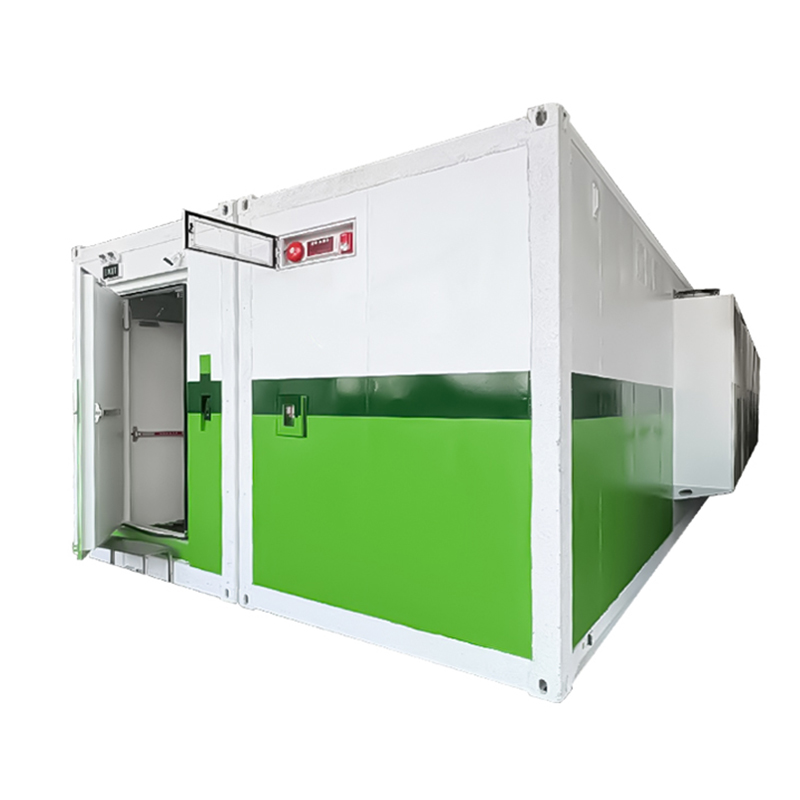

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

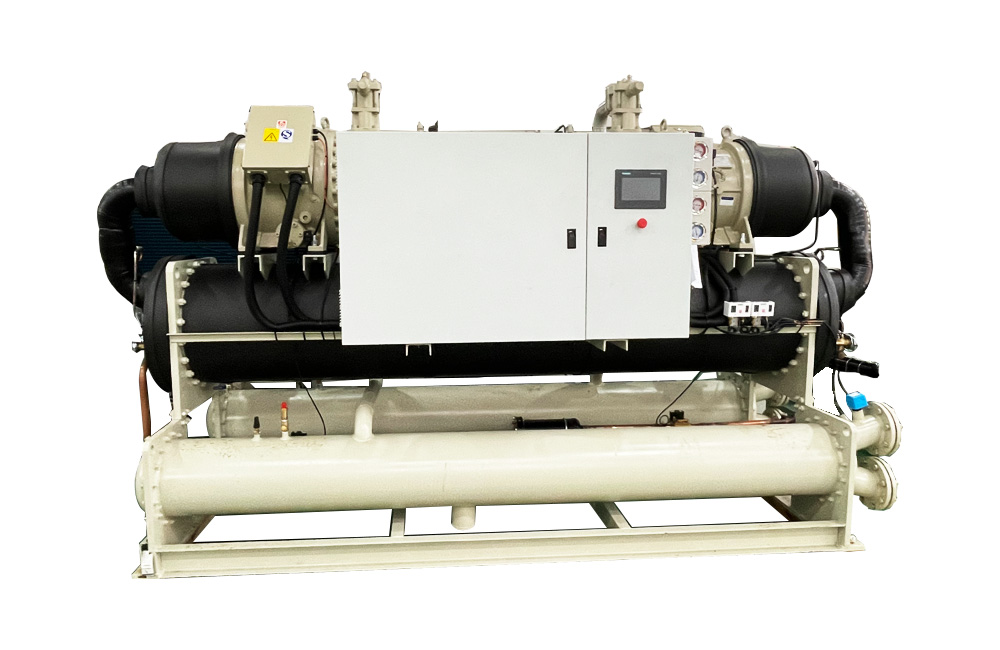

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Introduction:

The Heat Pipe Air Conditioning Unit is an energy-efficient air conditioning system designed to provide precise temperature and humidity control for facility rooms. It utilizes a high-efficiency refrigeration system that leverages natural cooling sources and meets the continuous 24/7 operational requirements. It is an ideal choice for green data centers and various electronic equipment rooms.

Application:

● Small and medium-sized computer rooms

● Four electrical rooms

● Battery rooms

● Substations

● Control rooms

● Equipment rooms

● High-end communication base stations, and various types of equipment rooms

Features:

During the summer, it uses compressor cooling with an energy efficiency ratio of ≥3.2 to ensure controlled room temperature. In the winter, it employs a heat pipe for natural cooling with an energy efficiency ratio of up to 11.0, maximizing energy savings. It is suitable for use in a wide temperature range, with indoor-outdoor temperature differences of ≥5°C, enabling the heat pipe mode.

The "large-area wide-body air delivery" design optimizes airflow organization through CFD simulation.

It can reliably operate in outdoor temperatures ranging from -35°C to 45°C, with an even broader low-temperature range.

It features an auto-start function upon power restoration, eliminating the need for manual intervention.

Standard electrical metering capability is included, providing visible energy savings and consumption reduction.

Technical Data:

|

FHF Heat pipe integrated Aircon |

|||

|

Indoor unit model |

FHF060 |

FHF080 |

FHF130 |

|

Main power supply |

220V1Ph~50Hz |

380V3Ph~50Hz |

|

|

Air supply |

Downward and front air supply |

||

|

Performance parameter |

|||

|

Cooling capacity(kW) |

6.0 |

8.0 |

13.0 |

|

Sensible capacity(kw) |

5.52 |

7.36 |

11.7 |

|

Max. operation current FLA(A) |

11.1 |

10.5 |

10.7 |

|

Compressor QTY |

1 |

||

|

Fan type |

DC axial flow fan |

||

|

Fan QTY |

1 |

2 |

2 |

|

Circulating air volume(m³/h) |

2400 |

3000 |

4000 |

|

Heating capacity(kW) |

2 |

||

|

Humidification(kg/h) |

|

||

|

Connecting pipe size |

|||

|

Liquid pipe(mm) |

19.05 |

||

|

Gas pipe(mm) |

12.7 |

12.7 |

15.88 |

|

Drain pipe |

Inner diameter 19mm, outer diameter 25mm, Metal hose clamp connection |

||

|

Indoorunit Dimension and Weight |

|||

|

Dimension-W(mm) |

580 |

||

|

Dimension-D(mm) |

360 |

||

|

Dimension-H(mm) |

1800 |

||

|

Weight(kg) |

92 |

103 |

121 |

|

Outdoor unit performance parameter |

|||

|

Outdoor unit model |

FKF060K0YA1 |

FKF080KOYA1 |

FKF130K0YA1 |

|

Dimension-W(mm) |

728 |

||

|

Dimension-D(mm) |

405 |

||

|

Dimension-H(mm) |

1145 |

1145 |

1370 |

|

Weight(kg) |

41 |

48 |

56.5 |

|

Electronic element specification |

|||

|

Air switch recommended(A) |

25 |

||

|

Indoor power cable diameter(mm²) |

2*2.5+1*2.5 |

4*2.5+1*2.5 |

4*2.5+1*2.5 |

|

Outdoor power cable diameter(mm3 |

2*1.0+1*1.0 |

||

|

Note: |

|||

Downloads

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)