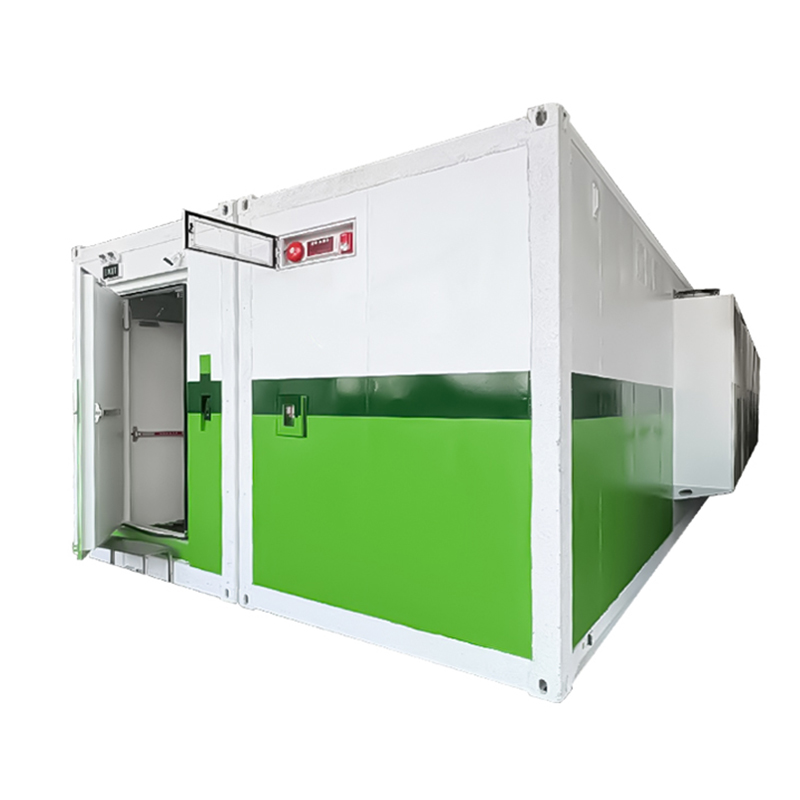

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

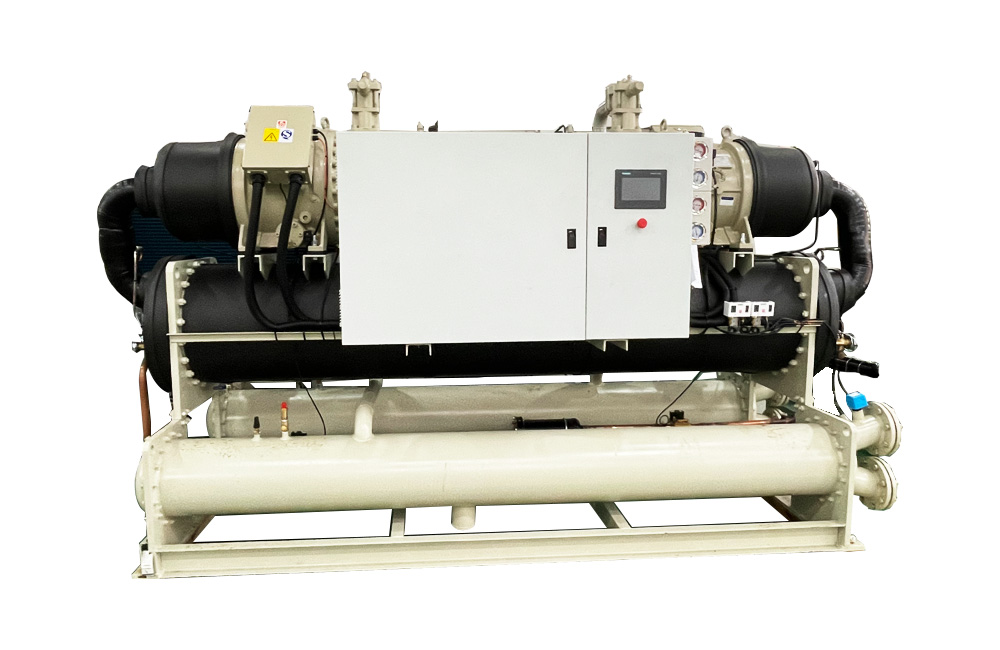

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

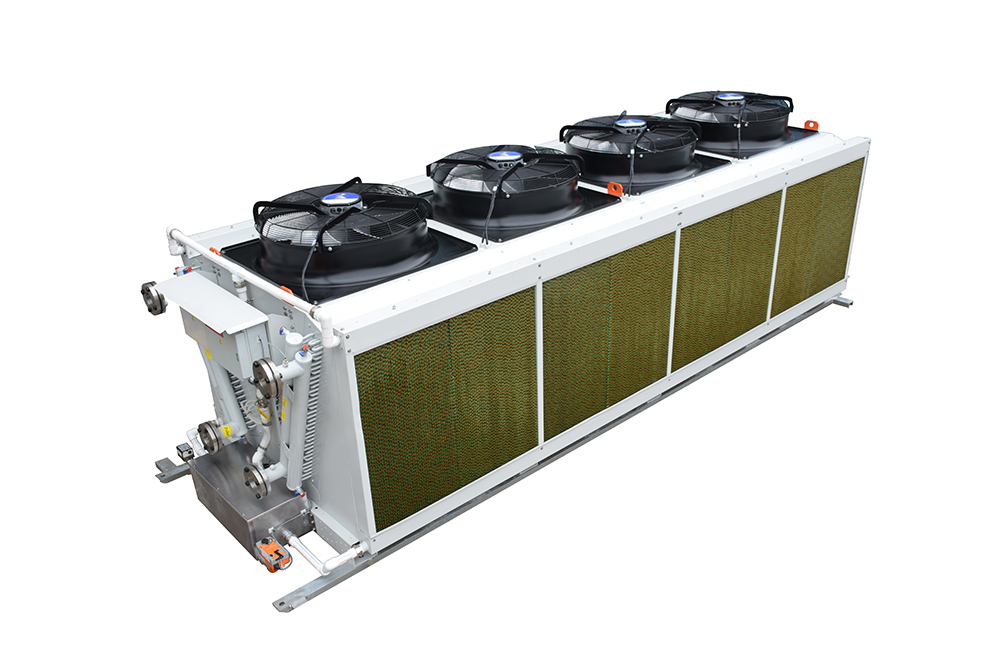

Features

1. High precision mold and high impact combination, reasonable fin shape, adjustable fin pitch

2. Mechanical expansion pipe, expansion, and contraction rate of more than 5%. Good heat transfer coefficient is ensured by close cooperation

3. Focus on the production of various national and non-standard heat exchangers

4. Fast delivery and strong adaptability;

5. Reasonable price and guaranteed service

About VENTTK

VENTTK is a leading design and manufacturing company specializing in Tube Fin Heat Exchangers.

Our experienced engineers use Italy's cutting-edge Mcoil thermal calculation software to design top-notch heat exchangers. With their expertise, we are able to produce precise drawings and performance calculation books.

Regarding production, we have state-of-the-art facilities that house multiple production lines dedicated to finned tube heat exchangers.

Our sheet metal production lines are equipped with advanced laser cutting machines, CNC punch presses, CNC bending machines, and stretching hydraulic devices for guide rings.

Additionally, our tube-expanding equipment includes both mechanical and hydraulic tube expanders.

VENTTK employs gas welding and argon arc welding techniques, and we also offer spray coating and electrophoretic processes to meet our customers' unique requirements.

At VENTTK, quality is our priority. Our Tube Fin Heat Exchangers are of the highest standard and hold international certifications such as Rohs, CE, and UL, which are widely recognized across the globe.

Material

|

Tube |

Smooth/inner grooved Aluminum |

|

Nickel-copper tube |

|

|

Titanium |

|

|

SUS304/316L |

|

|

Fin |

Aluminum foil/hydrophilic aluminum foil |

|

Aluminum-magnesium alloy |

|

|

Epoxy resin anti-corrosion aluminum foil |

|

|

Electrophoretic anti-corrosion aluminum foil |

|

|

Copper foil/tinned copper foil |

|

|

SUS304/316L |

|

|

Frame |

Galvanized steel |

|

Aluminum |

|

|

SUS304/316L |

Fin pattern

No. |

Tube Specification |

Hole Layout |

Fin Distance |

Fin suface |

|

1 |

7 |

25*21.65 |

1.4~3mm |

Sine wave and window |

|

21*12.7 |

1.2~2.5mm |

Flat, sine wave and window |

||

|

25*21.65 |

1.4~3mm |

Sine wave and window |

||

|

2 |

7.94 |

25.4*15.88 |

1.8~3mm |

Flat, sine wave and window |

|

19.05*22 |

1.8~3mm |

Flat, sine wave and window |

||

|

3 |

9.52(3/8”) |

19.05*16.5 |

1.4~4mm |

Sine wave and window |

|

25*21.65 |

1.8~7mm |

Flat and sine wave |

||

|

25.4*22 |

1.5~5.5mm |

Flat, sine wave and window |

||

|

25.4*12.7 |

1.5~5.5mm |

Flat, sine wave and window |

||

|

4 |

12.75(1/2”) |

31.75*27.5 |

1.5~8mm |

Flat and sine wave |

|

38.1*33 |

1.5~9mm |

Flat and sine wave |

||

|

5 |

15.88(5/8”) |

38.1*33 |

1.8~9mm |

Flat and sine wave |

|

50*50 |

2.5~12mm |

Flat and sine wave |

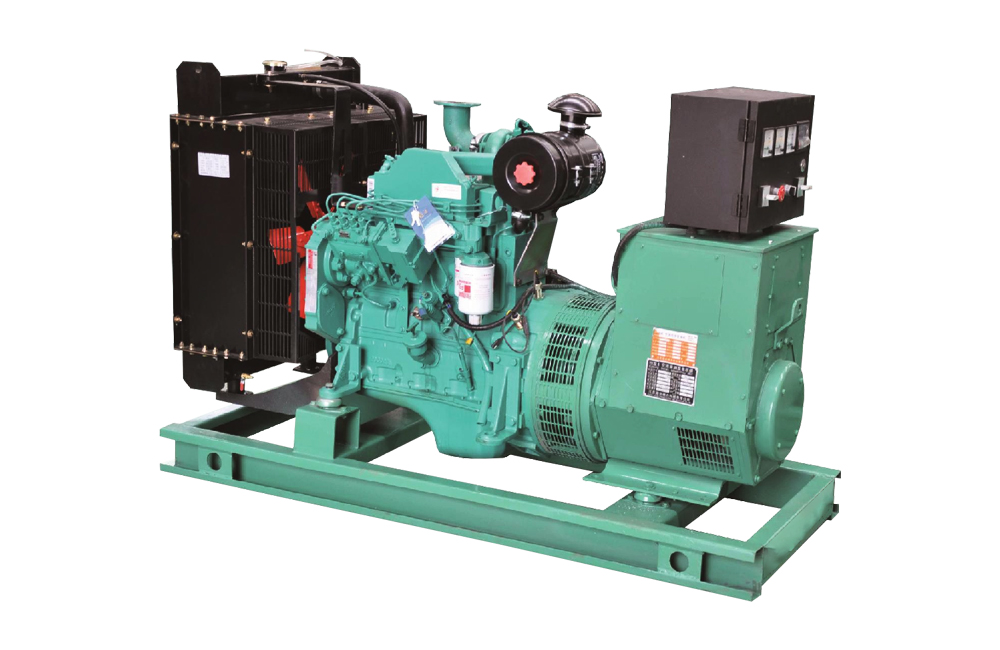

Application

Venttech Fin Heat Exchanger can be used for:

1. Combined air handling units, fan coil unit, and other air conditioning devices

2. Heat transfer in cold storage and all kinds of low-temperature systems

3. Energy recovery systems

4. Drying operation conditions, fresh air dehumidification

5. Industry and commerce air conditioning system

6. Vehicles, ships, and other transportation equipment

Downloads

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)