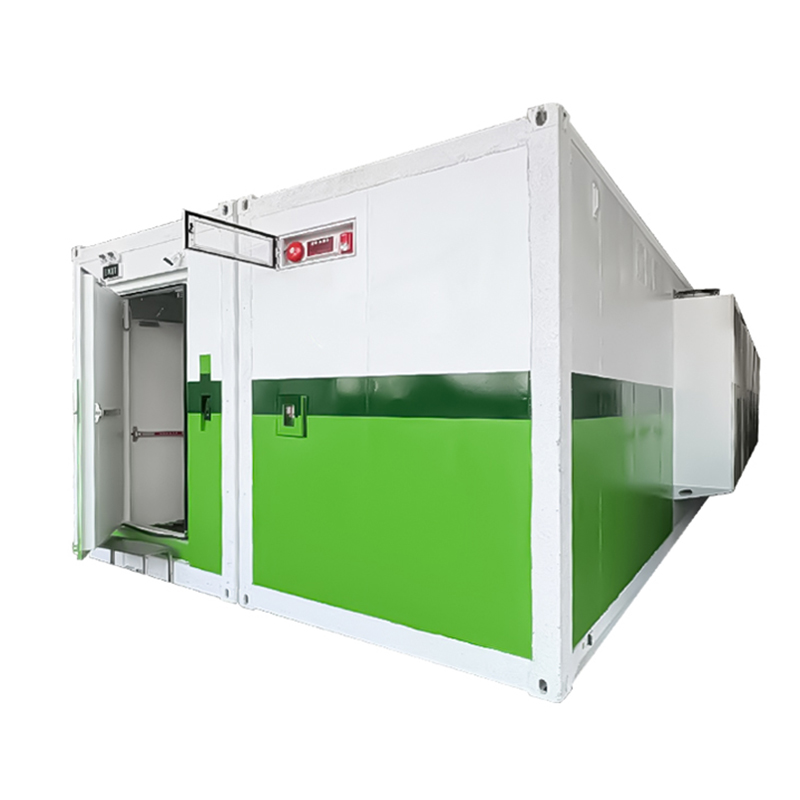

- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

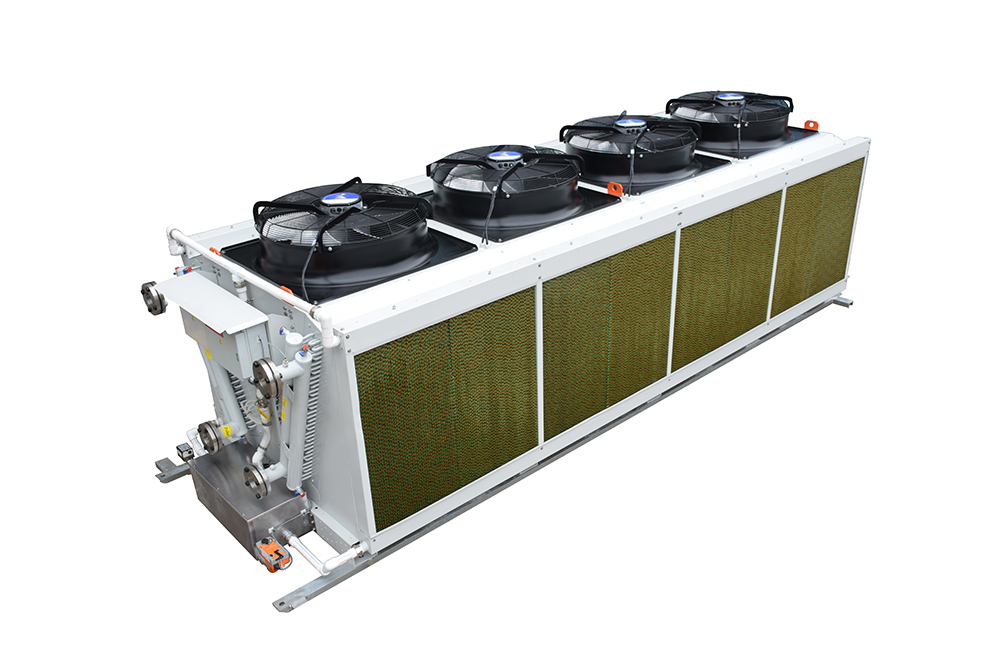

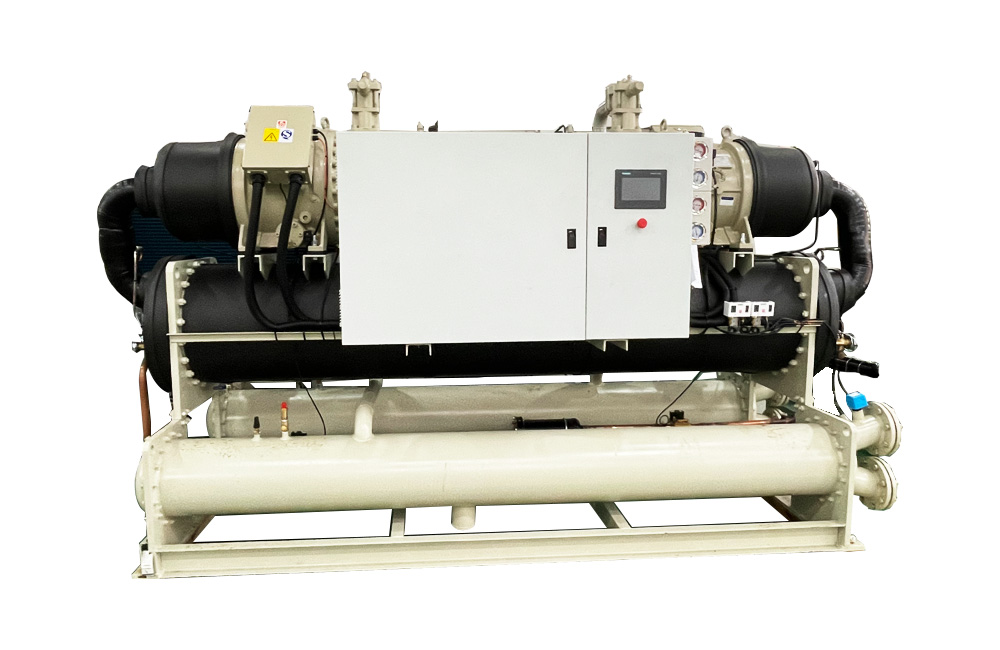

A free cooling chiller is a type of cooling system that utilizes ambient air temperature to provide cooling without the need for mechanical refrigeration.

It works by drawing in cool outdoor air and using it to lower the temperature of the cooling medium, such as water or glycol, which is then circulated through the building or process equipment to remove heat.

The key feature of a free cooling chiller is its ability to take advantage of the natural cooling capacity of the environment, reducing or eliminating the need for traditional mechanical cooling methods. This results in significant energy savings and lower operating costs.

Free cooling chillers are commonly used in applications such as data centers, industrial processes, and commercial buildings with a year-round cooling load.

Key Features of VENTTK Free Cooling Screw Chiller

1. Cooling capacity from 260~550kW, providing efficient cooling for various cooling loads.

2. Hanbell Screw compressor, ensuring efficient operation and long-lasting performance.

3. Free cooling function can start at 0℃ or 5℃, when the outside temperature is within this range, the chiller can use the cool outdoor air to supplement or replace mechanical refrigeration, significantly reducing energy consumption.

Part List

|

No. |

Name |

Brand |

Feature |

|

1 |

Compressor |

Hanbell |

Semi enclosed screw type, efficient and reliable |

|

2 |

Shell and tube heat exchanger |

Saft |

Efficient shell and tube heat exchanger (dry/falling film) |

|

Yinggu |

|||

|

3 |

Fin Heat Exchanger |

Shenglin |

Internally threaded copper tube, hydrophilic aluminum foil, high efficiency, and less prone to scaling |

|

4 |

Electronic expansion valve |

Sanhua |

High precision, precise control, long lifespan, rapid adjustment, and sharp response |

|

5 |

Pressure sensor |

Sensata |

Stable performance |

|

Sanhua |

|||

|

6 |

Axial fan |

Xingxin |

Compact structure, low noise, high efficiency |

|

Kemao |

|||

|

7 |

Safety valve |

Castel |

Stable quality, safe and reliable |

|

8 |

Electric three-way valve |

Johnson Controls |

Low resistance and reliable action |

|

9 |

Water pump |

CNP |

High efficiency and stable quality |

|

10 |

Dry filter |

Sanhua |

High dryness, replaceable filter element |

|

Dun An |

|||

|

11 |

Flow switch |

Anchao |

Stable quality and long lifecycle |

|

Kaobo |

|||

|

12 |

Controller |

Punp |

Stable performance and reliable quality |

|

Syslab |

|||

|

13 |

Contactor |

Schneider |

Stable performance and reliable quality |

|

Siemens |

|||

|

14 |

Thermal relay |

Schneider |

Stable performance and reliable quality |

|

Siemens |

|||

|

15 |

Circuit breaker |

Schneider |

Stable performance and reliable quality |

|

Siemens |

| Model | LSBLGFC***BGS | 260 | 280 | 300 | 320 | 340 | 390 | 430 | 460 | 550 | |

| Nominal Cooling Condition |

Cooling Capacity | kW | 257 | 276 | 302 | 322 | 339 | 389 | 432 | 464 | 543 |

| USRT | 73 | 79 | 86 | 92 | 97 | 111 | 123 | 132 | 155 | ||

| kBtu/h | 875 | 942 | 1031 | 1099 | 1158 | 1328 | 1474 | 1584 | 1853 | ||

| Cooling Input Power | kW | 86 | 97 | 103 | 106 | 114 | 128 | 143 | 154 | 181 | |

| IDC Working Condition |

Cooling Capacity | kW | 257 | 276 | 302 | 322 | 339 | 389 | 432 | 464 | 543 |

| Free Cooling 5℃ |

Ambient Temperature | 5℃ | |||||||||

| Cooling Capacity | kW | 180 | 193 | 212 | 226 | 238 | 273 | 302 | 325 | 380 | |

| Input Power | kW | 19.8 | 24.2 | 24.2 | 24.2 | 28.2 | 35.2 | 39.6 | 39.6 | 44.0 | |

| Free Cooling 0℃ |

Ambient Temperature | 0℃ | |||||||||

| Cooling Capacity | kW | 277 | 298 | 327 | 348 | 367 | 421 | 467 | 502 | 587 | |

| Input Power | kW | 19.8 | 24.2 | 24.2 | 24.2 | 28.2 | 35.2 | 39.6 | 39.6 | 44.0 | |

| Power Supply | 3N~/ 380V/ 50Hz | ||||||||||

| Maximum Input Power | kW | 125 | 140 | 150 | 154 | 165 | 186 | 208 | 223 | 262 | |

| Maximum Input Current | A | 216 | 243 | 259 | 266 | 285 | 322 | 360 | 387 | 454 | |

| Compressor | Model | Semi Enclosed Screw Compressor | |||||||||

| Quantity | Unit | 1 | |||||||||

| Start Mode | Y-△ | ||||||||||

| Energy Regulation | 25%-100% | ||||||||||

| No. of Refrigerant Circulation Circuits | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Evaporator | Type | Shell and Tube Heat Exchanger | |||||||||

| Water Flow Rate | m3/h | 52.9 | 57.0 | 62.4 | 66.5 | 70.1 | 80.4 | 89.2 | 95.9 | 112.2 | |

|

IDC Water Side |

kPa | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | |

| Connecting Pipe Diameter |

DN | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 150 | |

| Fan | Type | Axial Fan | |||||||||

| Quantity | 4 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 10 | ||

| Total Air Volume | m3/h | 97480 | 104920 | 114920 | 122480 | 129000 | 148000 | 164200 | 176480 | 206480 | |

| Fan Total Power | kW | 8.8 | 13.2 | 13.2 | 13.2 | 13.2 | 13.2 | 17.6 | 17.6 | 22.0 | |

| Refrigerant | Type | R134a | |||||||||

| Charge | kg | 83 | 89 | 97 | 104 | 109 | 125 | 139 | 150 | 175 | |

| Water Pump | Input Power | kW | 11.0 | 11.0 | 11.0 | 11.0 | 15.0 | 22.0 | 22.0 | 22.0 | 22.0 |

| External Head | m | 23 | 23 | 25 | 23 | 23 | 27 | 26 | 25 | 24 | |

| Net Dimension | L | mm | 2762 | 4108 | 4108 | 4108 | 4108 | 4108 | 5524 | 5524 | 6870 |

| W | mm | 2260 | 2260 | 2260 | 2260 | 2260 | 2260 | 2260 | 2260 | 2260 | |

| H | mm | 2540 | 2540 | 2540 | 2540 | 2540 | 2540 | 2540 | 2540 | 2540 | |

| Net Weight | kg | 2800 | 3200 | 3600 | 3800 | 4050 | 4200 | 5100 | 5673 | 7073 | |

| Running Weight | kg | 2940 | 3360 | 3780 | 3990 | 4253 | 4410 | 5355 | 5956 | 7426 | |

Notes:

1. The designed secondary refrigerant is 45% ethylene glycol, which meets the minimum environmental temperature of -30 ℃ for antifreeze requirements. If there are other operating parameters required, please contact us.

2. Nominal cooling condition: ambient temperature is 35℃,secondary refrigerant inlet/outlet temperature is 12/7℃.

IDC cooling condition: secondary refrigerant inlet/outlet temperature is 15/10℃.

Free cooling: secondary refrigerant inlet/outlet temperature is 15/10℃.

3. The maximum working pressure on the water side of the chiller is 1.0MPa, and the fouling coefficient is 0.018 m2 ℃/kW.

4. Applicable ambient temperature range:-30~46℃;

5. If there are changes due to improving product performance, please refer to the parameters on the nameplate of the chiller.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)