Immersion Container System

Experienced and professional engineers, passionate R&D teams, competitive price with good quality,and cooperation experience with customers from all over the world.

Products

Company Profile

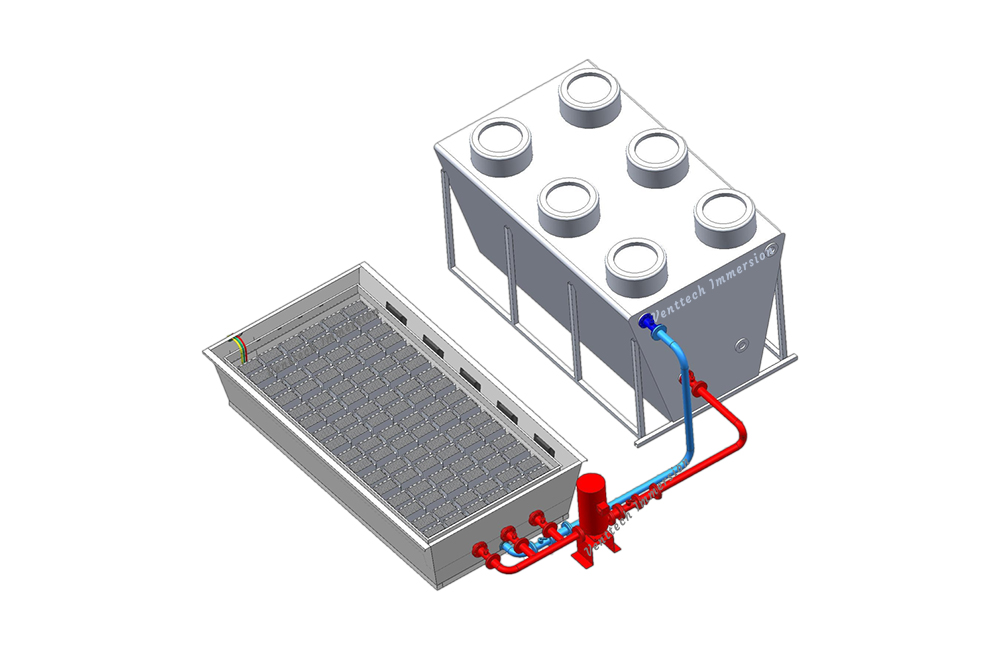

Dry Coolers

Air Cooled Heat Exchangers

Shell and Tube Heat Exchangers

Coolant Distribution Units (CDUs)

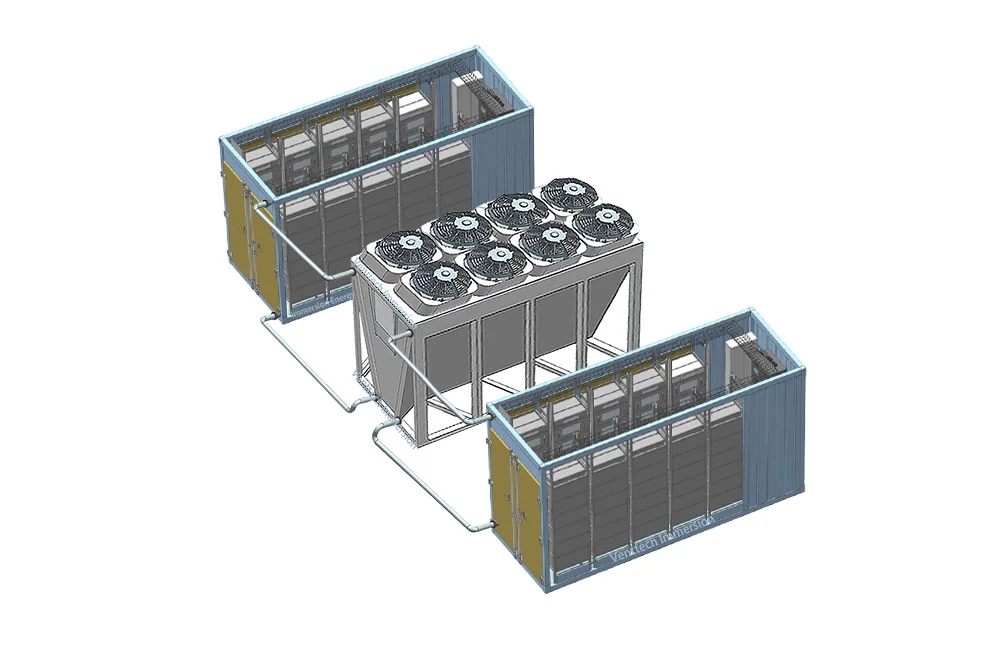

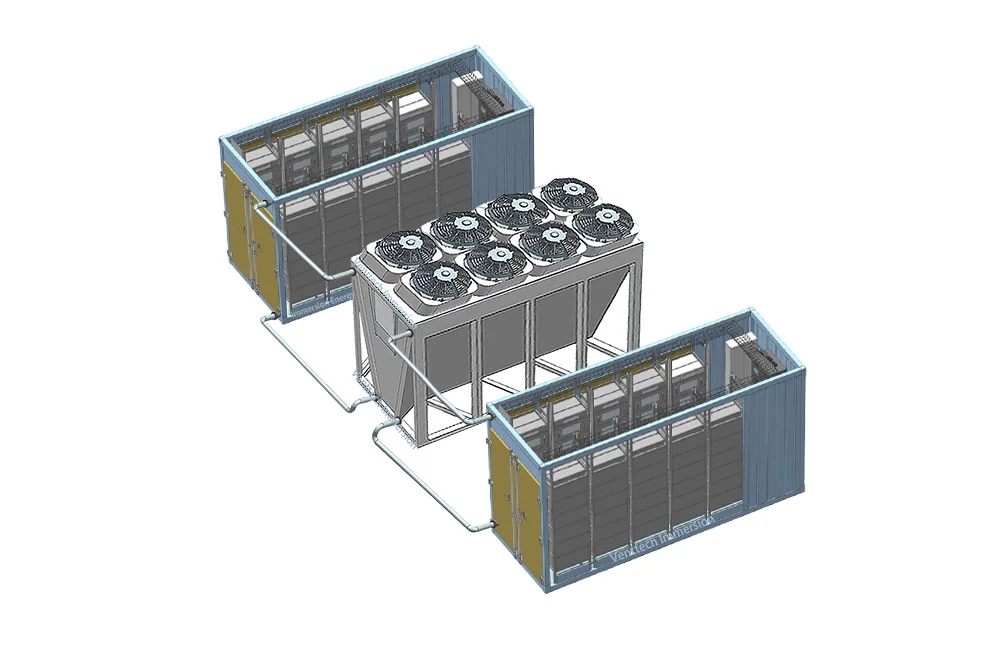

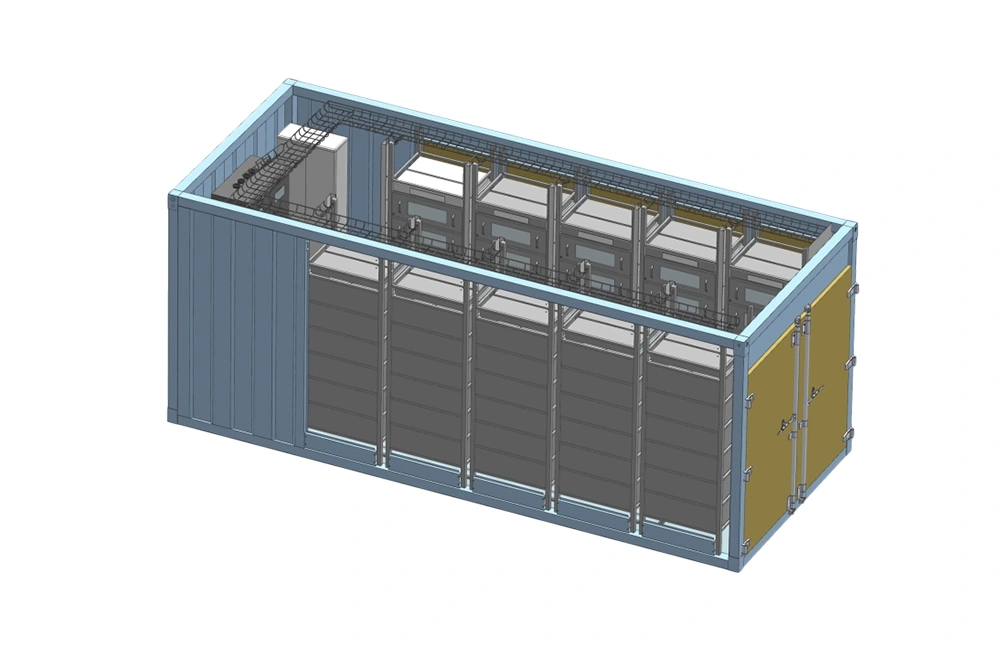

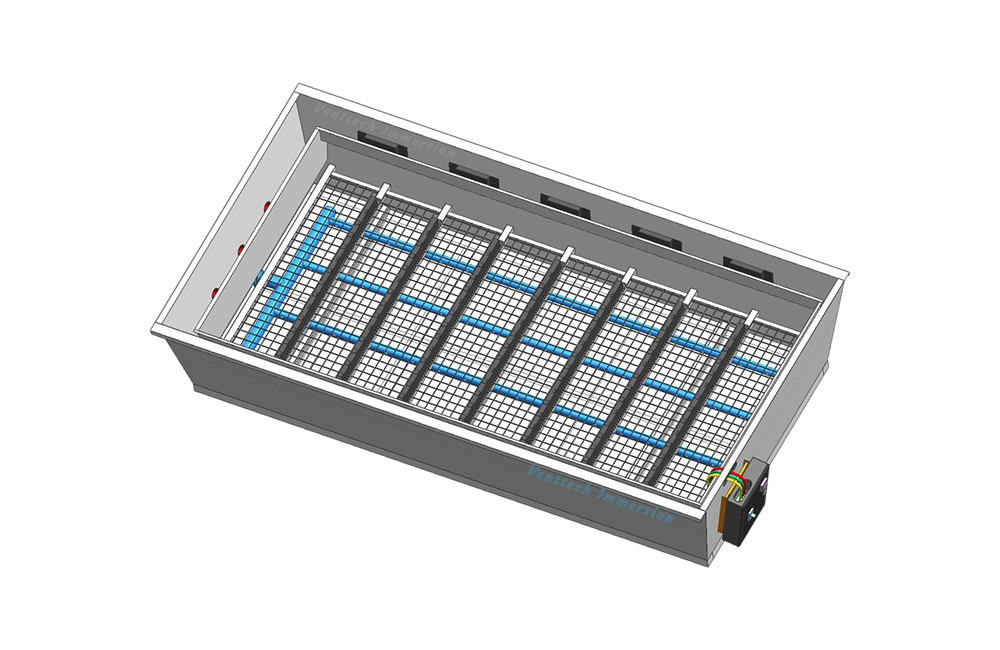

Immersion Cooling Containers

Precision Cooling and Control

Water-Cooled Cabinets for Data Center

Data Centre Coolants

Prefabricated Data Centers

Tube Fin Heat Exchangers

Cooling Towers

Chillers

Generator Sets

Packaged Rooftop Units

Microchannel Heat Exchangers

Microchannel Shows

Fin Heat Exchangers

Tube Fin HX by Applications

Hot Product

Dry coolers are the most cost-effective way to dissipate heat from immersion cooling systems.

Immersion cooling, also known as liquid immersion cooling, submerges computer components or entire servers in a thermally conductive but nonconductive liquid (dielectric coolant), which offers higher heat transfer properties than air and many other advantages.

Performance range:

● Capacity from 69to 3212kW

(water, Tw1=40°C, Tw2=35°C, T1=25°C)

Fans:

● Diameter Ø630, 800, 910, 1250, 1800mm, AC or EC motor.

Benefits:

● Maximum performance, minimum footprint.

● High efficiency geometry.

● Modular design, 1~28 fans.

● Piping in copper or stainless steel AISI 304 or AISI 316L.

● Finned pack available in a wide range of materials.

Options:

● Coil design refrigerant: water, oil, glycol, BC888, Shell S3X, and so on.

● Multiple circuits.

● Sub-cooling circuits.

● Stainless steel or aluminum casing.

● Epoxy resin aluminum or copper fins.

● Explosion proof motor.

● Customized fin spacing.

mic.jpg?x-oss-process=image/resize,w_100/quality,q_100)