- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

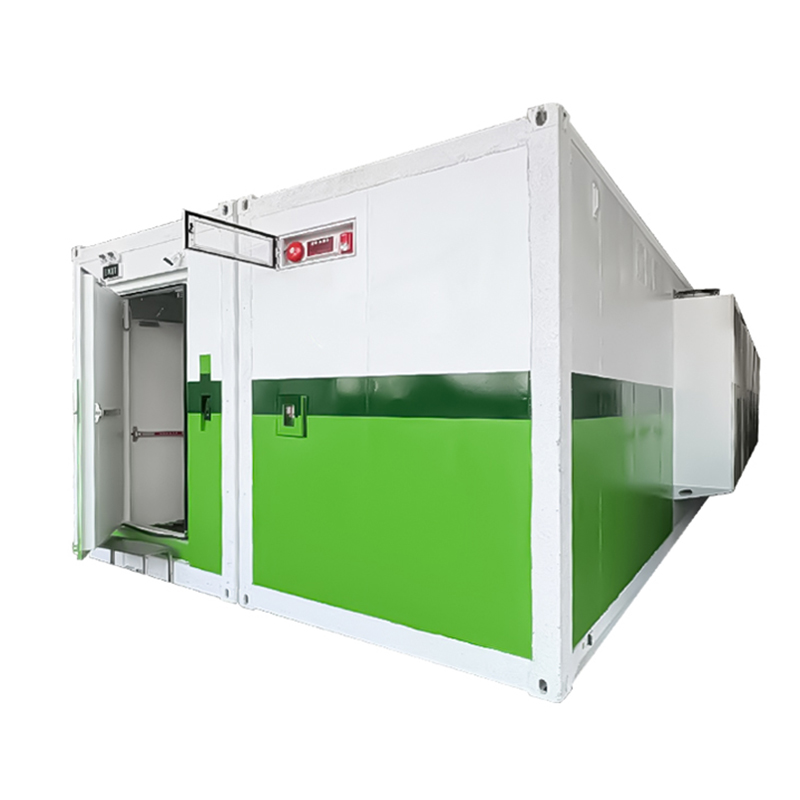

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Product Description

Low Viscosity Immersion Coolant is made of hydrocarbon and other materials. This product can be used directly.

|

PROPERTIES

|

TYPICAL DATA

|

TEST METHOD

|

|

Appearance

|

Clear and transparent,

no sediment and suspension

|

Visual estimation

|

|

Density(25℃),g/cm3

|

0.792 |

GB/T 1884

|

|

Kinematic viscosity(40℃)

/(mm2/s) |

4.96 |

GB/T 265

|

|

Pour point/℃

|

-65 |

GB/T 3535

|

|

Flash point (opening)/℃

|

182.5 |

GB/T 3536

|

|

Ignition point/℃

|

191.2 |

GB/T 3536

|

|

Breakdown voltage (2.5mm)/kV

|

41.7 |

GB/T 507

|

|

Volume resistivity(60℃),Ω·m

|

6.78*10^14 |

DL/T 421

|

|

Relative dielectric constant(90℃)

|

1.984 |

GB/T 5654

|

|

Dielectric loss factor

|

0.006 |

GB/T 5654

|

|

Acid value/ mg/g KOH

|

0.015 |

GB/T 264

|

|

Copper corrosion(100℃,3h)

|

1b |

GB/T 5096

|

|

Thermal conductivity(40℃,W/m.K)

|

0.1335 |

ASTM D2717

|

|

Specific heat capacity(40℃,J/g.K)

|

2.05 |

ASTM E2716

|

|

Density correction factor((g/cm3)/℃)

|

0.000673 |

ASTM D1250

|

|

Vapour pressure(150℃,mm/Hg)

|

18 |

ASTM D2879

|

Note: Customized products for other working conditions are available.

Downloads

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)