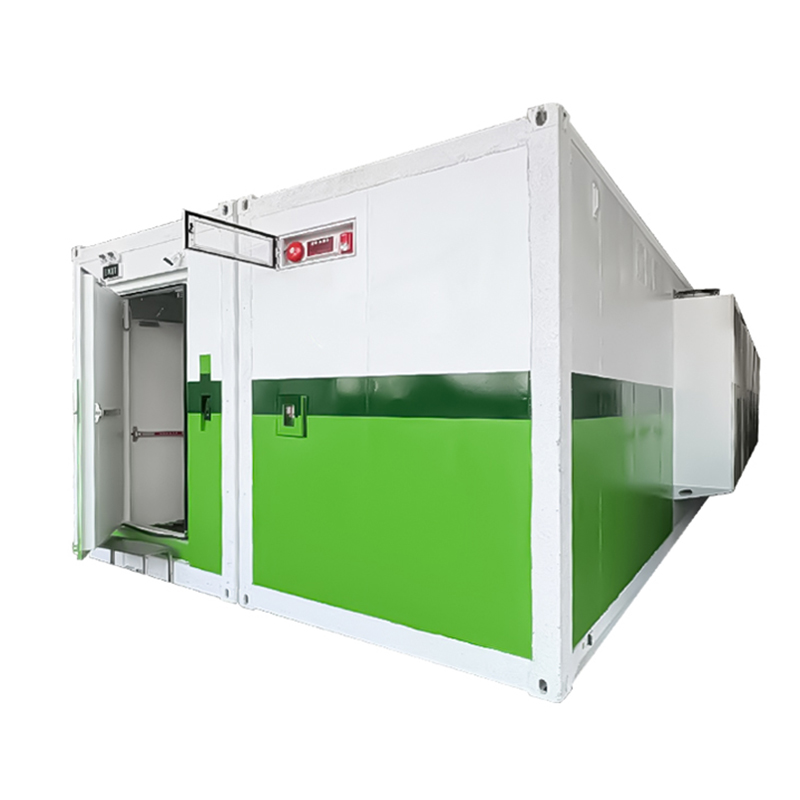

- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

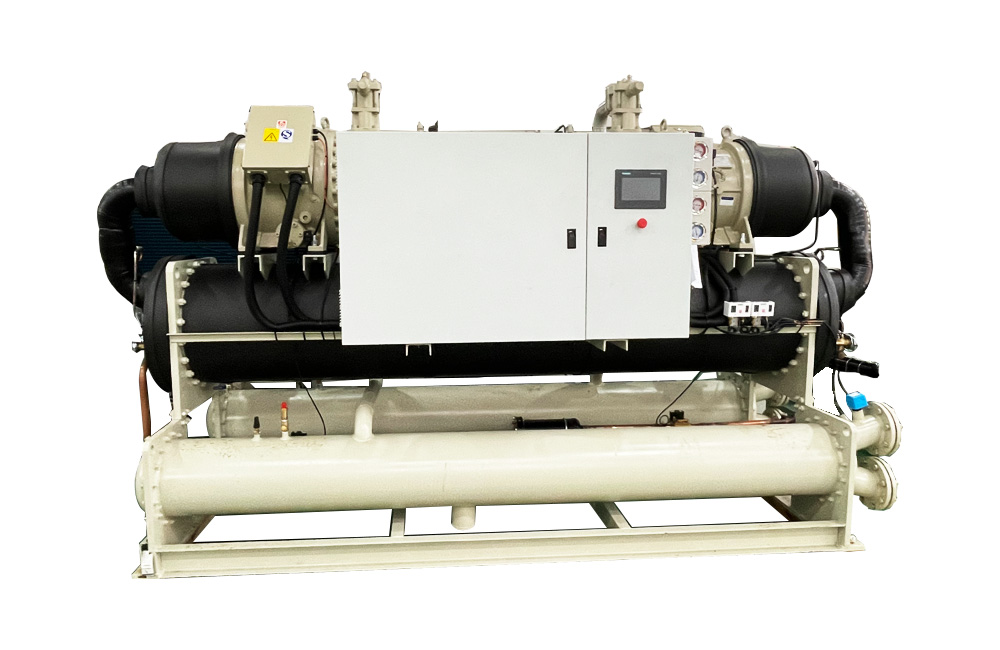

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Introduction

The Coolant Distribution Unit (CDU) is a crucial component in cooling systems, primarily functioning in the secondary side of the circulation.

In a typical cooling system, there are two main loops: the primary side and the secondary side. The primary side is usually connected to the main cooling sources such as chillers or cooling towers, which provide the initial cooling medium. The secondary side is connected to the equipment that requires cooling, such as servers, electronic devices, etc., ensuring these devices operate at optimal temperatures.

The CDU plays a vital role in the secondary side by distributing the cooling medium from the primary side to the equipment needing cooling, achieving efficient heat exchange. Its core components include variable frequency circulating pumps, plate heat exchangers, temperature and pressure sensors, filters, expansion tanks, and flow meters. The CDU not only ensures effective distribution of the coolant but also provides online liquid replenishment, maintaining system stability.

Additionally, the CDU features an intelligent control system that can monitor and adjust temperature, flow, and differential pressure in real-time, preventing condensation and supporting various communication protocols for seamless integration with other systems. Its corrosion-resistant, high-quality materials and modular design make it suitable for various industrial and commercial environments, ensuring efficient cooling and long-term operation of equipment. Choosing a CDU means opting for an efficient and reliable cooling solution.

Performance Range

· Heat Transfer Capacity:350~1500kW

Features

· 10-inch Touch Screen: Multi-level authority control, easy to operate.

· Modular Design: Flexible expansion according to demand.

· High-Efficiency Variable Frequency Pump (Optional): Dual backup pumps automatically adjust flow rate, ensuring efficient operation.

· Dual Power Supply Backup (Optional): Enhances system reliability.

· Corrosion-Resistant Materials: Made with 304 stainless steel and above, ensuring long service life.

· Intelligent Control System: Includes temperature monitoring, secondary side temperature control, flow and differential pressure control, anti-condensation protection, and optional monitoring for conductivity, water turbidity, water hardness, and pH value.

· Ultra-Quiet Motor: Low noise and long service life, suitable for quiet environments.

· Standard Communication Protocol: Supports Modbus TCP, with comprehensive detection, alarm, and protection functions. Setup parameters are automatically protected, and operational parameters and alarm records are retained after power failure.

· Customizable Monitoring Protocol: Special format monitoring protocols can be customized according to customer requirements.

· Secondary Side Filtration Precision: Ultra-wide design range of 25~100μm, meeting various application needs.

Our Advantages

With Venttk's innovative design, the CDU optimizes the performance and reliability of the water cooling system. It features six channels that connect the main circuit to the secondary water distributor of the water-cooled cabinet, reducing installation and production errors with the use of chucks and rubber hoses.

Venttk's CDU incorporates a multi-stage centrifugal pump for industrial water circulation, ensuring efficient and reliable coolant flow. An integrated expansion tank compensates for temperature fluctuations, maintaining stable pressure levels and ensuring reliable system operation.

To prevent issues such as oxidation corrosion, poor circulation, and cavitation of the circulation pump, the CDU includes an automatic air vent valve on the top of the makeup water tank/main pipeline, which promptly eliminates non-condensable gases from the system.

Additionally, the CDU is equipped with a 150μm filter in the main path to protect the quality of the coolant, ensuring the reliable and stable operation of the entire system.

Choose Venttk's Coolant Distribution Unit (CDU) for a more efficient and reliable water cooling system.

PDC, Liquid Cooling Rack Power Distribution Cabinet

Water-cooled cabinets are specially customized server enclosures and power distribution units (PDUs) that feature highly integrated structures for improved reliability.

| Functional items | Parameter | Specification |

| Electrical parameters | input voltage | 400V±10% |

| input current | Max 1200A | |

| frequency | 50Hz | |

| output voltage | 400V±10% | |

| Output digits | 20 bits | |

| Working environment | Operating temperature | -10~45℃ |

| Operating humidity | 5-100%RH | |

| altitude | 0–3000 m | |

| Safety regulations and certificates | Certificates and Declarations | CE |

| User interface | display screen | |

| Operate the key | ||

| communication interface | ||

| Temperature and humidity interface | ||

| Light | ||

| Electrical parameter measurement and control function | PDU Total Measurements | Voltage, current, power, and electrical energy |

| Measurements of each phase | Voltage, current, power, and electrical energy | |

| Each output can be remotely controlled on / off | ||

| The user can customize the power / down timing and interval of each output | ||

| The output unit can be grouped for control | ||

| Administrator rights can be defined by levels | ||

| Custom alarm signal threshold | Current can be set | |

| Cascade function | RS485 | |

The design and main materials of the distribution cabinet meet CE certification requirements, including plastic case circuit breakers, miniature circuit breakers, current transformers, energy meters, indicator lights, emergency stop buttons, emergency stop protective covers, surge protectors fans, and terminals.

The low voltage distribution cabinet is used for power, lighting, and distribution energy conversion and control in accordance with the voltage distribution system requirements of the product model. This product has strong breaking ability, good dynamic and thermal stability, flexible electrical scheme, convenient combination, strong series and practicality, and novel structure.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)

mic.jpg?x-oss-process=image/resize,w_100/quality,q_100)