- Immersion Cooling Container

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

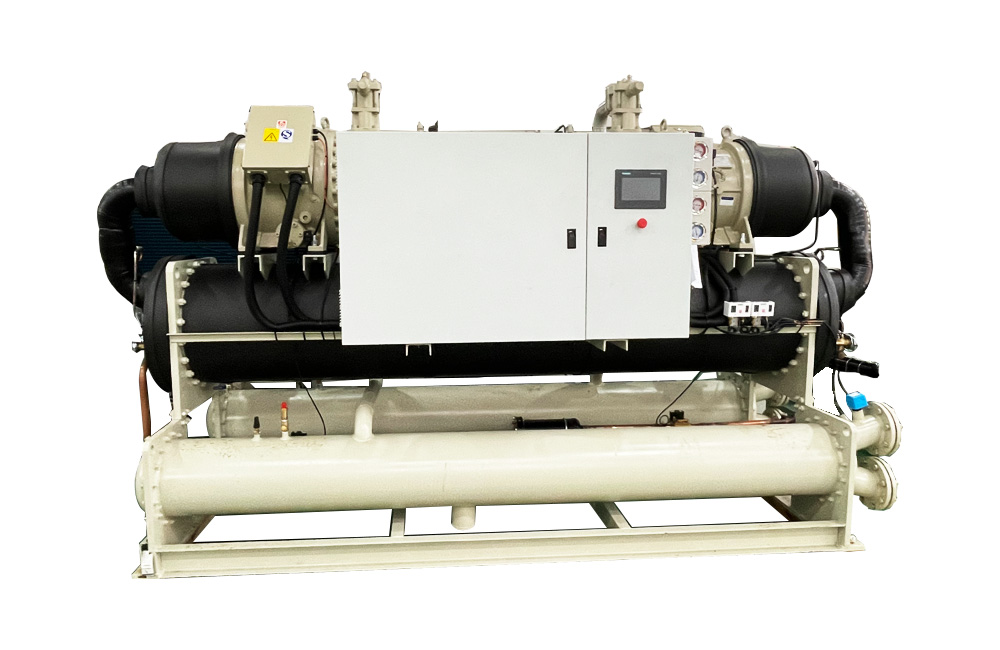

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

Features

Serpentine evaporator coil is a type of heat exchanger that utilizes plates and finned chambers to transfer heat between fluids, usually gases. It features "sandwiched" passages with fins to enhance performance. Available designs include crossflow and counterflow, with various fin configurations such as straight, offset, and wavy fins.

Serpentine heat exchangers are the most compact and versatile solution for 3kW heat rejection or cooling. They are ideal for use in refrigerant condensers, evaporators in compressorized and pumped loop systems, and non-condensing cooling applications, delivering excellent heat transfer efficiency, reliability, and ease of integration.

Venttech offers customized serpentine evaporator coils tailored to client specifications. Our manufacturing facility has the capacity to produce up to 150 tons per month and provides a one-year warranty.

● Automobile air conditioning systems

● Electronics cooling

Core Structure and Material

Basic Elements of a Serpentine Evaporator Coil:

Fin Material: Aluminum, Stainless Steel

Plate/Header: Aluminum, Stainless Steel

Solder: Stainless Steel

Advantages

● High heat transfer efficiency especially in gas treatment

● Less space occupation and lighter weight

● Saving heat transfer costs and investment costs

● Able to withstand high pressure

● Convenient maintenance

Application

● Agricultural machines, tractors, and forestry equipment

● Construction machines

● Automotive industry

● Railway equipment (trains)

● Compressors

● Hydraulic Systems

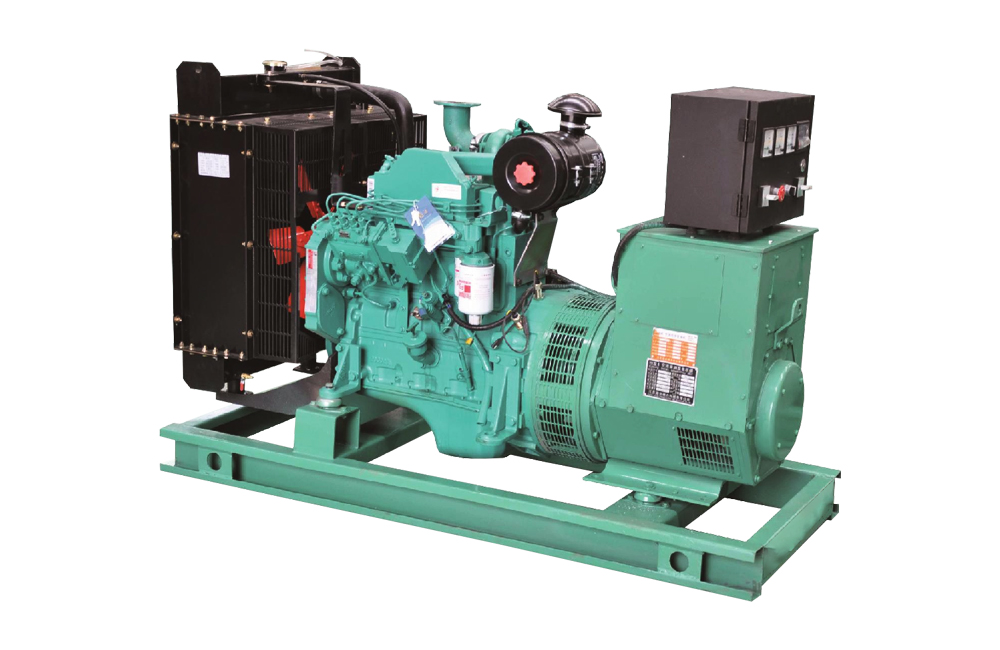

● Power generator sets (gen-sets)

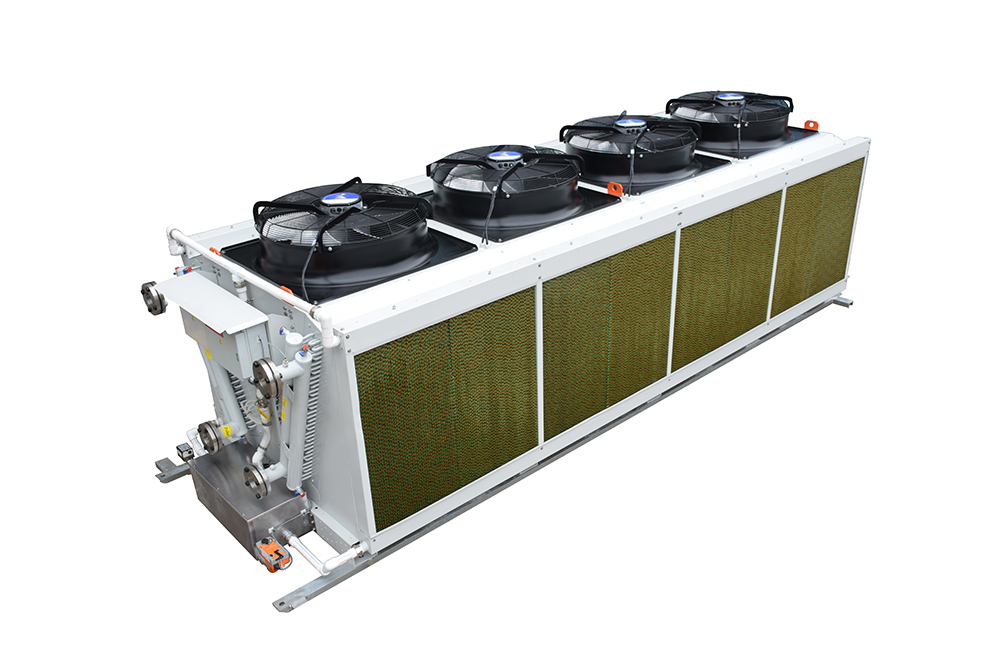

Combined cooler for hydraulic, oil pressure, water cooling, intercooler, and other systems in construction machinery, such as excavators, vibratory rollers, truck cranes, drilling rigs

|

Flow rate (L/min) |

Working Pressure (Mpa) |

Overall Dimension (mm) |

Heat dissipation area (m2) |

|

100 |

3.6 |

400 x 340 x 80 |

8.3 |

|

160 |

3.6 |

520 x 395 x 100 |

13.2 |

|

200 |

3.6 |

500 x 425 x 100 |

14.7 |

|

250 |

3.6 |

630 x 500 x 95 |

20 |

|

315 |

3.6 |

730 x 500 x 95 |

23 |

|

350 |

3.6 |

740 x 550 x 100 |

27.2 |

|

400 |

3.6 |

723 x 806 x 100 |

47.9 |

|

500 |

3.6 |

650 x 965 x 90 |

36 |

Multiple mounting and connection options available.

Excavator Oil Cooler

Model for excavator series:

|

|

Engine Power(kW) |

Design Pressure (Mpa) |

Transfer Area (m2) |

|

0.8~2T |

10~20 |

1.6 |

1.5~4.5 |

|

3.5~5.5T |

25~33 |

1.6 |

3.5~15 |

|

6T |

30~45 |

1.6 |

10~25 |

|

7~8T |

40~60 |

1.6 |

18~30 |

|

10~13T |

75~95 |

1.6 |

28~40 |

|

20T |

90~120 |

1.6 |

35~45 |

|

22~23T |

100~140 |

1.6 |

40~60 |

|

33T |

200 |

1.6 |

90~105 |

Venttech’s Excavator Oil Coolers can also meet the requirements of the use of coal mine fields, such as explosion-proof, anti-corrosion, and anti-static.

Concrete Mixer Oil Cooler

Concrete mixer trucks series Oil cooler

|

Model |

Fuel tank capacity |

Fan diameter |

Fan motor voltage |

|

WB021 |

18L |

305 mm |

24/12 V |

|

WX026 |

25L |

305 mm |

12/24 V |

The assembly integrates the cooler, oil tank, fan, air guide, fan shield, temperature switch, and filter. The oil tank and radiator are integrated, and the filter is connected to the oil tank through a flange.

Each model is equipped with 1 heat exchanger, 1 fan, 1 filter, 1 thermal switch, 1 anti-shock block

Single-phase AC motor for multiple smaller and three-phase models for larger cooling surfaces.

For corrosive applications, special versions of plate heat exchangers are available for marine and anti-corrosion environments.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)