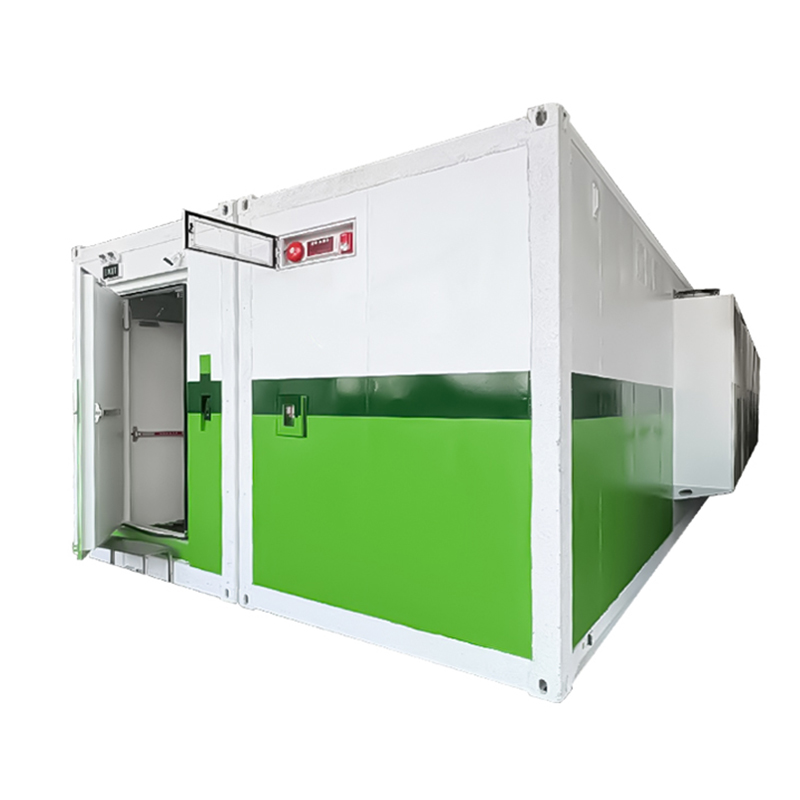

- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

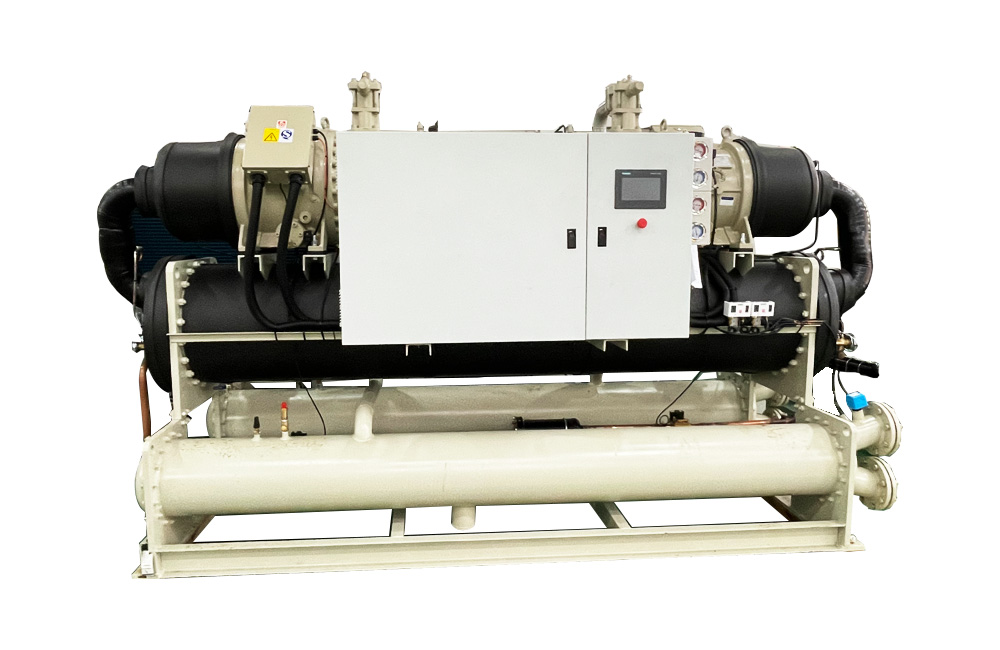

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Our Shell and Tube Heat Exchangers are designed and manufactured in strict accordance with ASME standards, with U Stamp certification included. The products are engineered to deliver reliable performance in demanding marine applications as well as industrial processes.

Product Highlights

● Types: Plate, Spiral Plate, Threaded Locking-Ring, and Shell & Tube Heat Exchangers.

● Shell & Tube Subtypes: Fixed Tube-Sheet, U-Tube, Floating Head, etc.

● Materials:

Duplex Stainless Steel + Carbon Steel for marine-grade durability

Non-ferrous options: Titanium, Nickel, Copper, Aluminum, Molybdenum, Zinc, Cobalt, and their alloys

● Design Pressure: Low / Medium / High Pressure

● Design Temperature: Low / Medium / High Temperature service

● Medium Compatibility:

Non-flammable, non-toxic, non-corrosive fluids

Flammable, toxic, corrosive, and even highly hazardous media

Medium Compatibility

● Marine Condensers

● Coolers & Heaters

● Preheaters & Vaporizers

● Reboilers & Evaporators

● Dryers & Steam Equipment

● Solvent Preheaters, Gas Furnace Water Jackets, and more

Quality Assurance

All products undergo rigorous inspection with a third-party witness available:

● Material certification with supplied material samples

● Mechanical tests

● NDT (PT & RT)

● Hydrostatic pressure testing

● Dimensional inspection report

Additional quality control documentation can be provided upon customer request.

Technical Data(Heat transfer tube Φ20)

| Nominal diameter(mm) | Number of tube passes | Number of tube | Center row tube number | Tube side flow area | Heat transfer area Heat transfer tube length(mm) |

||||

| 1500 | 2000 | 3000 | 4500 | 6000 | |||||

| 159 | 1 | 15 | 5 | 0.0030 | 1.4 | 1.9 | 2.8 | ||

| 219 | 1 | 33 | 7 | 0.0066 | 3.1 | 4.1 | 6.2 | ||

| 273 | 1 | 65 | 9 | 0.0131 | 6.1 | 8.2 | 12.3 | 18.4 | 24.5 |

| 2 | 56 | 8 | 0.0056 | 5.3 | 7.0 | 10.6 | 15.8 | 21.1 | |

| 325 | 1 | 99 | 11 | 0.0199 | 9.3 | 12.4 | 18.7 | 28.0 | 37.3 |

| 2 | 88 | 10 | 0.0088 | 8.3 | 11.1 | 16.6 | 24.9 | 33.2 | |

| 4 | 68 | 11 | 0.0034 | 6.4 | 8.5 | 12.8 | 19.2 | 25.6 | |

| 400 | 1 | 174 | 14 | 0.0350 | 16.4 | 21.9 | 32.8 | 49.2 | 65.6 |

| 2 | 164 | 15 | 0.0165 | 15.5 | 20.6 | 30.9 | 46.4 | 61.8 | |

| 4 | 146 | 14 | 0.0073 | 13.8 | 18.3 | 27.5 | 41.3 | 55.0 | |

| 450 | 1 | 220 | 17 | 0.0477 | 22.3 | 29.8 | 44.7 | 67.0 | 89.3 |

| 2 | 220 | 16 | 0..0221 | 20.7 | 27.6 | 41.5 | 62.2 | 82.9 | |

| 4 | 200 | 16 | 0.0101 | 18.8 | 25.1 | 37.7 | 56.5 | 75.4 | |

| 500 | 1 | 275 | 19 | 0.0553 | 34.6 | 51.8 | 77.8 | 103.7 | |

| 2 | 256 | 18 | 0.0257 | 32.2 | 48.3 | 72.4 | 96.5 | ||

| 4 | 222 | 18 | 0.0112 | 27.9 | 41.8 | 62.8 | 83.7 | ||

Technical Data(Heat transfer tube Φ25)

| Nominal diameter(mm) | Number of tube passes | Number of tube | Center row tube number | Tube side flow area | Heat transfer area Heat transfer tube length(mm) |

||||

| 1500 | 2000 | 3000 | 4500 | 6000 | |||||

| 159 | 1 | 11 | 3 | 0.0038 | 1.3 | 1.7 | 2.6 | ||

| 219 | 1 | 25 | 5 | 0.0087 | 2.9 | 3.9 | 5.9 | ||

| 273 | 1 | 38 | 6 | 0.0132 | 4.5 | 6.0 | 9.0 | 13.4 | 17.9 |

| 2 | 32 | 7 | 0.0055 | 3.8 | 5.0 | 7.5 | 11.8 | 15.1 | |

| 325 | 1 | 57 | 9 | 0.0197 | 6.7 | 9.0 | 13.4 | 20.1 | 26.9 |

| 2 | 56 | 9 | 0.0097 | 6.6 | 8.8 | 12.3 | 19.8 | 26.4 | |

| 4 | 40 | 9 | 0.0035 | 4.7 | 6.3 | 9.4 | 14.1 | 18.8 | |

| 400 | 1 | 98 | 12 | 0.0039 | 11.5 | 15.4 | 23.1 | 34.6 | 46.2 |

| 2 | 94 | 11 | 0.0163 | 11.1 | 14.8 | 22.1 | 33.2 | 44.3 | |

| 4 | 76 | 11 | 0.0066 | 9.0 | 11.9 | 17.9 | 26.9 | 35.8 | |

| 450 | 1 | 135 | 13 | 0.0468 | 15.9 | 21.2 | 31.8 | 47.7 | 63.6 |

| 2 | 126 | 12 | 0.0218 | 14.8 | 19.8 | 29.7 | 44.5 | 59.4 | |

| 4 | 106 | 12 | 0.0092 | 12.5 | 16.7 | 25.0 | 37.5 | 50.0 | |

| 500 | 1 | 174 | 14 | 0.0603 | 27.3 | 41.0 | 61.5 | 82.0 | |

| 2 | 164 | 15 | 0.0284 | 25.8 | 38.6 | 58.0 | 77.3 | ||

| 4 | 144 | 15 | 0.0125 | 22.6 | 33.9 | 50.9 | 67.9 | ||

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)