- Immersion Cooling Containers

- W40 Hydro Cooling Container

- Tower-Inside Immersion Cooling Container

- Rack X Hydro Cooling Container

- Immersion Cooling System

- Immersion Cooling Plant Type 1.1MW

- Immersion Cooling Plant Type 1.0 MW

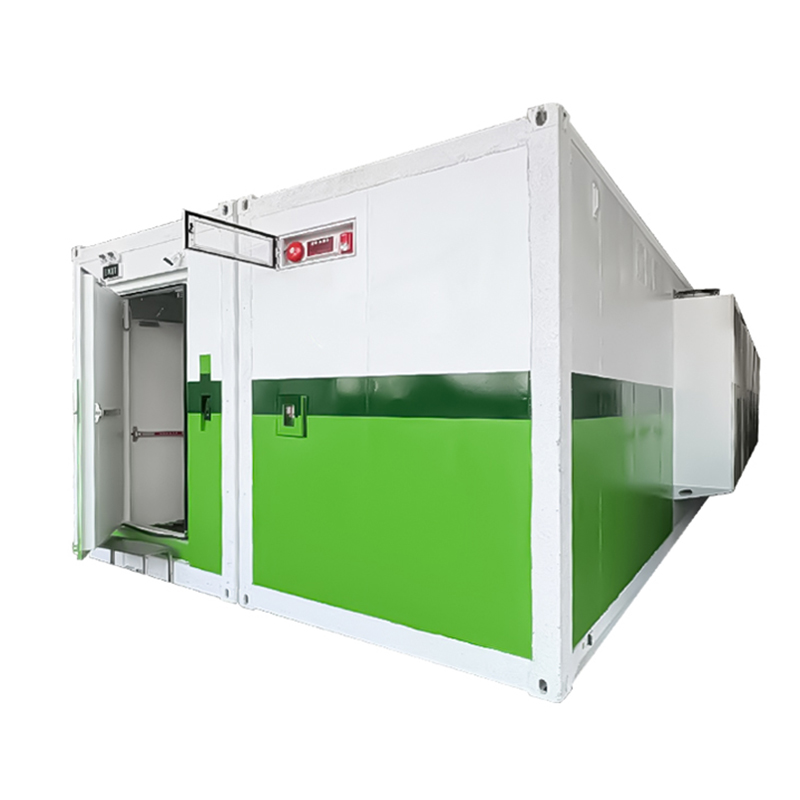

- Immersion Cooling Container 1.1MW/2.0MW

- Immersion Cooling Container

- Hydro Cooling Container

- Cabinet Cooling System

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Our Shell and Tube Heat Exchangers are designed and manufactured in strict accordance with ASME standards, with U Stamp certification included. The products are engineered to deliver reliable performance in demanding marine applications as well as industrial processes.

Product Highlights

● Types: Plate, Spiral Plate, Threaded Locking-Ring, and Shell & Tube Heat Exchangers.

● Shell & Tube Subtypes: Fixed Tube-Sheet, U-Tube, Floating Head, etc.

● Materials:

Duplex Stainless Steel + Carbon Steel for marine-grade durability

Non-ferrous options: Titanium, Nickel, Copper, Aluminum, Molybdenum, Zinc, Cobalt, and their alloys

● Design Pressure: Low / Medium / High Pressure

● Design Temperature: Low / Medium / High Temperature service

● Medium Compatibility:

Non-flammable, non-toxic, non-corrosive fluids

Flammable, toxic, corrosive, and even highly hazardous media

Medium Compatibility

● Marine Condensers

● Coolers & Heaters

● Preheaters & Vaporizers

● Reboilers & Evaporators

● Dryers & Steam Equipment

● Solvent Preheaters, Gas Furnace Water Jackets, and more

Quality Assurance

All products undergo rigorous inspection with a third-party witness available:

● Material certification with supplied material samples

● Mechanical tests

● NDT (PT & RT)

● Hydrostatic pressure testing

● Dimensional inspection report

Additional quality control documentation can be provided upon customer request.

Water-Cooled vs. Air-Cooled Heat Exchangers

Which One to Choose?

● Air-cooled systems are recommended for water-scarce or high-temperature regions, offering low maintenance costs and zero water consumption.

● Water-cooled shell-and-tube exchangers are ideal when lower outlet temperatures, compact installation, or reliable water supply are required.

● We also offer hybrid (dry/wet) air-cooled systems for enhanced performance in hot climates.

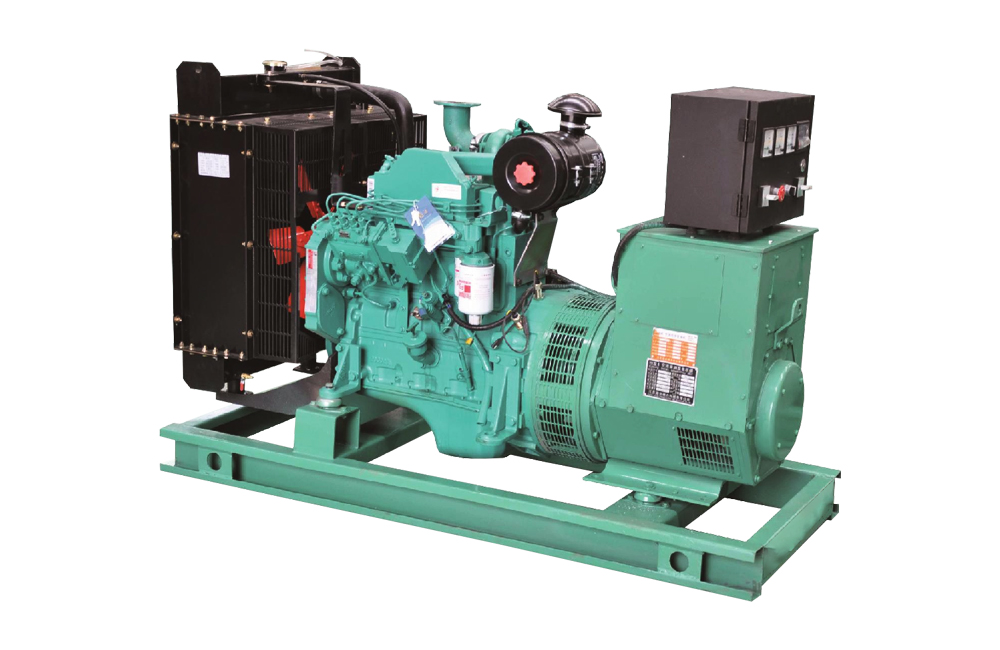

Supporting Products:

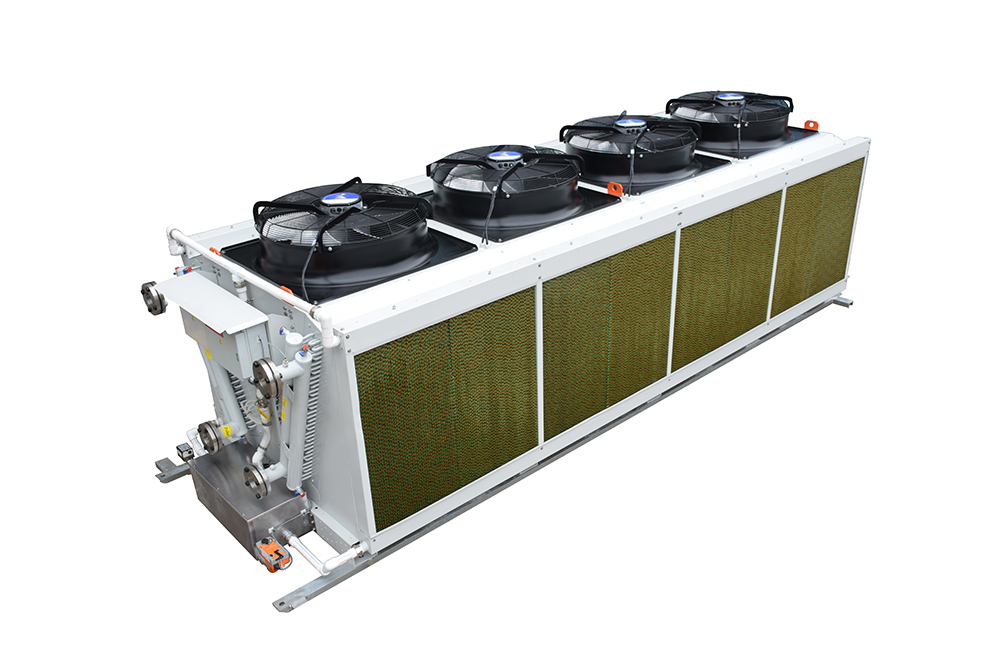

● Air Fin Cooler / Dry Cooler

● Shell and Tube Heat Exchanger

● Plate Heat Exchanger

● Hybrid Cooling Systems (Dry + Spray)

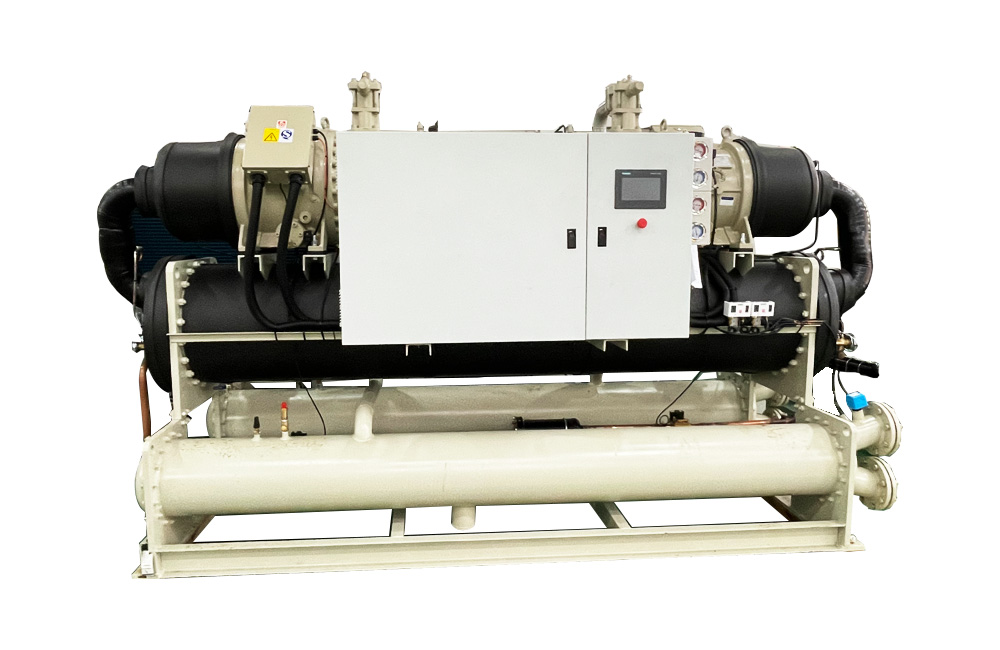

Shell-and-Tube Water-Cooled Heat Exchangers

Advantages

● High cooling efficiency: outlet temperature can approach wet-bulb conditions

● Compact design: smaller footprint, easily integrated into tight spaces

● Stable performance: unaffected by ambient temperature fluctuations

● Quiet operation: no fans, minimal noise

Limitations

● High water consumption and pollution risk

● Needs water source, pumps, pipelines, and treatment systems

● Corrosion & scaling: frequent maintenance and chemical treatment required

● Total shutdown upon power failure

● Biological growth risk in warm climates

Air-Cooled Heat Exchangers (Dry Coolers, Air Fin Coolers)

Advantages

● Environmentally friendly: no water consumption, no thermal or chemical pollution

● Site flexibility: suitable for arid areas or water-scarce regions

● Easy maintenance: corrosion-free, scaling-free, long service life

● Lower operating costs: air has low resistance and no treatment cost

● Passive cooling: retains 30–40% natural cooling even when power is off

Limitations

● Cooling is limited by dry-bulb temperature; it cannot cool below ambient

● Requires a larger footprint due to low air-side heat transfer

● Affected by weather: wind, sunlight, and seasonal changes impact performance

● Noise: due to fans and airflow

● Requires finned tubes and specialized fan systems

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

65.webp)

265.webp)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)