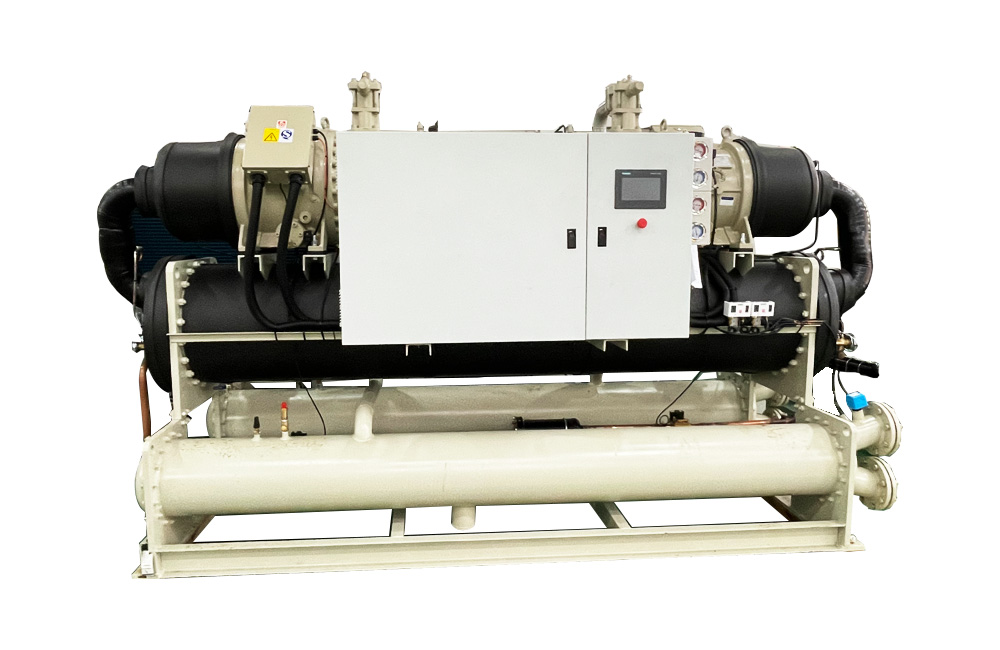

Computer Room Air Conditioners Direct Expansion Unit (DX CRAC)

CRAC DX unit utilizes the direct expansion cooling technology, where the refrigerant is compressed by a compressor into high-temperature and high-pressure gas. Then it expands through an expansion valve to become low-temperature and low-pressure gas, thereby achieving the desired cooling effect.It uses efficient compressors and is equipped with EC centrifugal fans to meet the continuous operation requirements 24x7. It is an ideal choice for green and energy-efficient data centers and various electronic equipment rooms.

![loading... [80x23]](https://shopsource.singoo.cc/1155/general/5NjB5mefwnJsrcBh.png?x-oss-process=image/resize)

.jpg)

.jpg)

![loading... [304x195]](https://shopsource.singoo.cc/1155/general/hNakAQcM6btHyDdd.jpg?x-oss-process=image/resize)